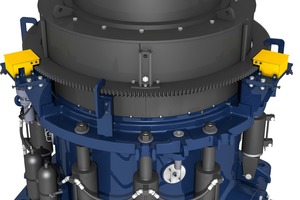

Improved safety, ease of maintenance and maximised throughput

While every crushing problem is unique, businesses within the aggregate and construction industries all want the same thing from their crushing solutions: safety, ease of maintenance and the highest possible throughput. The FLSmidth Raptor cone crusher line has long provided industries with effective crushing solutions that meet these demands. With the introduction of the new Raptor R250, R350 and R450 models, these advantages are further reinforced with advanced smart technologies and machine optimisation software.

The new Raptor cone crusher generation does not need back liner material for the liners and is designed to operate at higher capacities. In addition, the pressure resistance had been increased. This will improve the particle shape during the size reduction, something that can reduce the number of crushing stages and require smaller screen sizes in the plant. For tertiary crushing applications, a new generation of crusher liners have been designed. This had increased the crusher performance of several customers by 10 % and extended liner life by more than 40 %.

The Raptor R250, R350 and R450 also incorporate comprehensive digital connectivity like never before. Using the latest in smart technology, these cone crushes are cloud-based. This allows them to continuously provide operational, performance and asset health monitoring metrics, which can be accessed by authorised personnel at any time, and from anywhere in the world. Additionally, automation systems can use this data to optimise crusher performance and feed control, even taking corrective action when force overloads are detected. The end result is that businesses can improve productivity, while also lowering maintenance and monitoring costs.

The R250, R350 and R450 Raptor cone crushers use OEM software to ensure that the machine is operating at peak performance without risking damage. This software is capable of self diagnosis, and can be easily integrated with most plant systems. Additionally, the Raptor cone crushers employ “fail safe” hydraulics to ensure protection from mechanical overload should an accumulator bladder fail. The OEM software also helps maintain desired output through power-based control or particle size analysis, which automatically adjusts the close-side settings for increased consistency of particle size.

Providing the aggregate and construction industries with improved throughput and data visibility, while ensuring equipment safety and reduced maintenance expenses, the new Raptor cone crusher models are poised to revolutionise the entire crushing process. And, backed by FLSmidth‘s depth of experience and technical advisory services, businesses have easy access to the right knowledge to ensure that they implement the best cone crusher solutions to meet their needs.