Improved functionality

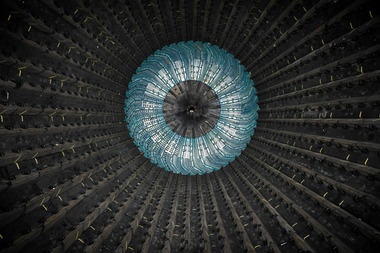

Metso’s Poly-Met shell lining concept MegalinerTM is now available for Semi-Autogenous (SAG) mills (Fig.). The patented system has proven to reduce lining change out time by 30 % to 40 %. “With the launch of the MegalinerTM for SAG mills, Metso can now supply this liner system to all large-scale mill applications that use modern 7- and 8-axis liner handlers,” says Tage Möller, Vice President of Mill Lining Solutions, Metso Mining and Construction. SAG mills are some of the largest mills around with the largest ones presently having a diameter of 42 feet with 28 MW installed power. The MegalinerTM bolts are inserted and removed from outside the mill, which greatly improves safety; workers do not need to stand in the drop-zone of the suspended liners. MegalinerTM is made from a rubber/metal composite that weighs between 30 % and 60 % less than metallic liners of a similar size. This means that more value-added grinding media can be carried, improving the mill‘s functionality.

Metso is also launching a completely new concept, the patented Liner Positioning System. This tool allows the liner handler operator to position the liner using cameras to view operations remotely. The new technology gives the liner handler operator full control of the process. This product is unique to Metso and only available to customers of its lining products.