High demands on silo filters

Modern filter systems for silos must achieve something: They not only ensure compliance with the emission limits, but also protect against overpressure. At the same time, a high quality and, consequently, value stability are decisive features of reliable filters. Demand-based solutions and the modernization of existing plants are necessary to meet the legal regulations and the requirements for product safety.

Whether sensitive food, coarse wood pellets or fine lime - silos are often the best choice for the intermediate storage of bulk solids of any kind. They securely protect the goods against undesired influences from outside and, at the same time, they prevent dust and the contained hazardous substances from escaping into the atmosphere. Frequently, pipings are used to fill the silos. They pneumatically (with compressed air) convey the contents of the bulk container vehicles into the silo. An overpressure as well as dust is generated inside the silo due to blowing in of material. The amount of dust varies according to the kind of bulk solid, the amount of conveying air (the compressed air conveying the bulk solid) as well as the respective degree of filling of the pipe and of the silo. Martin Griskewitz, Project Manager Plant Engineering of F.O.S., explained that particularly attention must be paid as regards building materials: “A high degree of dust formation should be expected especially in case of fine products, such as cement, gypsum or chalk.”

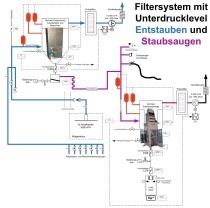

Efficient silo filters counteract the dangers of escaping hazardous substances by separating the majority of the dust. As opposed to external dedusting equipment beside the plants, the dust separated and cleaned by the silo filters falls back into the silo. Furthermore, they limit the pressure build-up inside the silo during filling, because the excess air can escape through the filter. Large filter surfaces are particularly effective for this purpose, since they reduce the back pressure during filling and they facilitate the cleaning in counterflow. Thus, cleaned dust particles may fall back unhindered into the silo and are not filtered repeatedly. Otherwise, the pressure inside the silo would be increase continuously.

Individual design

The filters are mainly mounted in the silo roof, or they are installed as an attachment on it. Their manufacture is always a precision job since the size as well as the fields of application vary. “At the beginning of any project, the silo is inspected and precisely measured. We always have to adapt the filters to the local civil conditions”, explained Griskewitz. The Ahlen-based F.O.S. Group has specialized in dust collection engineering and manufactures the adequate filters for any kind of silos. Depending on the product, different filter media, such as bags, envelopes, plates, cassettes or cartridges, will be used. The filter media are distinguished by high separating performances of up to 99.99 % even with fine and finest dusts.

The material of the filter media is decisive for the performance. F.O.S. mainly uses rigid or flexible membrane filter media of polyester fabric of different qualities and thicknesses. Furthermore, the company also uses other plastic materials, such as polypropylene (PP), polytetrafluorethylene (PTFE) and polyimide (PI). The so-called regenerated filter media are a unique feature: They are treated in special plants, which have been tested according to § 4 of the Federal Immission Control Act, so that they can be integrated again into the economic cycle. Thus, they become sustainable products since there is no thermal utilization, i.e. combustion. Furthermore, their use is clearly more favourable without being forced to forego quality. Internal test results of modern, regenerated filters correspond to those of new products.

User-friendly maintenance

One of the most important aspects regarding the procurement of silo filters is their ease of maintenance. “Operators of silos attach great importance to easy maintenance. Optimally filter plants are designed in such a way they can be maintained by one person only without any great expenditure”, said Griskewitz. After all the work is carried out at the top of the silo at a high altitude, where the technicians are exposed to the weather. By means of precautionary maintenance it can easily be established whether a replacement is required or not. A replacement is carried out if the filter media are damaged or worn out. Dust deposits at the clean gas end behind the filter are an indication of this. “We recommend our customers to regularly check the plant once a year”, underlined Griskewitz. Thus, filters may achieve a service life of around 20 years without any problem.

If the product to be stored is changed, it will also be necessary to install a new filter system. “Currently many operators convert their silos, e.g. from cleaning by shaking to compressed-air cleaning or pulse-jet cleaning”, said Griskewitz. The range of potential streamlining measures on existing plants is large, also beyond the pure silo filters. “From a plant extension up to an optimization of coverage points, there are many possibilities for the operators to increase the total performance of their filter systems”, explained Griskewitz. If, for instance, a conversion is planned from bags to cartridges, the filter surfaces must be increased. In case of a cleaning conversion from scavenging air to pulse jet, however, the filter heads have to be replaced.