Granulation of salts

In many industries, dust is produced that is either a reusable waste material in itself or still contains components that can be recovered and reused. Before these valuable materials can be handled or recovered, the dusts need to be agglomerated. In most cases, the dusts can simply be converted to granulate via build-up agglomeration in an Eirich mixer.

Eirich mixing technology

Eirich mixing technology

© Eirich

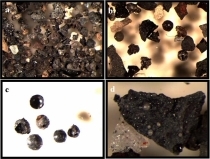

But in the past, build-up agglomeration was not an expedient solution when it came to agglomerating salts. Eirich has now developed a method using a feed of superheated steam to achieve high-strength granulates – of more than 30 N – using a combination of a mixer and a disk pelletizer. The method requires far less energy input than the use of crystallizers, and another advantage it offers is that further substances can be added at the build-up agglomeration stage and incorporated into the granules.

The Eirich test center at the company headquarters in Hardheim offers experience and know-how in the granulation of salts. Here, experienced process engineers are on hand for investigations with customer materials, which then form the basis for the planning of large-scale preparation systems. Systems with an output of up to 50 t/h have already been configured.