GEA Group

Rotary presses for all applications

GEA‘s R-series rotary tablet presses allow for extremely short cleaning and format changeover times and the tool-free disassembly and reassembly of all removable parts. The R55 is an exceptionally versatile industrial rotary press for a wide range of powder product processing applications, including nuclear fuel pellets, hard metals, catalysts, automotive parts, batteries and confectionery. The R55 rotary press can be supplied with a number of optional features to improve and expedite the tablet production process and provide higher levels of control.

Supply of turnkey plant for spray drying of lignosulfonate

The production of value-added products from renewable raw materials is one of Borregaard’s core competencies. GEA is supplying the Norwegian company with a turnkey plant for the spray drying of lignosulfonate in the double-digit million range. The solution also includes a new silo for feeding stored powder materials into the plant’s packaging system and a large wet scrubber for dust removal. The entire process solution will be installed at the Norwegian site in Sarpsborg. Commissioning is scheduled for mid-2019.

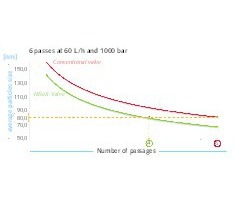

The NiSoX-Valve solution from GEA

After GEA had presented the homogenization innovation NiSoX-Valve at ACHEMA 2018, the results of the first field study will be available at the customer’s premises in time for POWTECH 2019. In the stress test of a real application, it was even possible to exceed the original laboratory results. The new NiSoX-Valve geometry optimizes energy distribution during homogenization, thereby reducing particle size and significantly improving the homogenization effect.

Solutions for flow components

GEA also presents further solutions for applications in the field of flow components, such as HYGIA & Cleaner (HP2), GEA Hilge CONTRA, GEA Hilge HYGIA (HP12) and VESTA Tank Bottom Display.

Hall 3 / 231