Flotation in times of circular economy and energy transition

Summary: The invention of flotation about 140 years ago was one of the great achievements of modern processing technology. For many metallic/mineral raw materials, processing without a flotation stage would be unthinkable. This article presents the especially important topics in the field of basic research and technological development of flotation in times of the circular economy and energy transition.

1 Resource-related challenges in the context of circular economy and energy transition

Humanity has always felt itself to be in the area of conflict between innovative technological developments aimed at positively influencing the quality of life, the limited available resources and the sometimes destructive effects on our environment. In 2011, motivated by the demonstrably severe impact on the Earth‘s climate of greenhouse gases, such as CO2 produced by the burning of fossil fuels, as well as the nuclear reactor disaster in Fukushima, political leaders called for a transition to renewable energies. This necessitates the large-scale employment of new technologies, such as electric cars, efficient wind turbines with magnets containing rare earths and highly networked, intercommunicating systems in the context of digitization. This development is strongly influencing the material mix and thus the raw material requirements. The complexity of the composite materials, with their extremely complex, polymetallic character and fine distribution of raw materials, is characteristic of many new technological developments, as famously exemplified by the material mix in smartphones, which contains numerous elements of the periodic table.

The availability of metals and mineral resources is a critical factor in a healthy economy, especially one which is also striving to be a circular economy. For thermodynamic reasons, such an economy cannot be closed, i.e. in addition to secondary resources, primary resources always have to play a role. This is shown schematically in the lead figure. This illustrates how the Helmholtz Institute Freiberg for Resource Technology (HIF) (marked in blue) addresses the subject of the value chain from metallic and mineral raw materials through to the product, and subsequently to the end of the product‘s life cycle in the context of the circular economy.

Important aspects of this are the topics of exploration, processing and metallurgy, as well as the interdisciplinary topic of recycling, combined with a fundamental analytical understanding of raw materials and complex mathematical modeling in the field of geometallurgy. There is a clear trend that in both the primary raw materials (natural mineral phases in ores) and the secondary raw materials (synthetic phases in end-of-life products) the intergrowths, i.e. the size of the phases, are getting finer and finer. For the raw material processing, this presents the challenge of being able to separate the ultrafine particles in a resource-efficient and energy-efficient manner, so that the future is not only fine-sized, but also fine in the sense of “good”, based on the play on words used at the flotation conference in 2015 “The future will be fine” (Wei Sung Ng, University of Melbourne, @MEI Flotation‘15).

One process that has been successfully separating fine and ultrafine particles for more than 100 years is flotation [1], which in its essential characteristics was patented in Dresden in 1877 for the processing of graphite. For this reason, the HIF decided to place a particular focus on this aspect of minerals processing research, partly due to the fact that flotation research had almost come to a standstill in post-reunification Germany. In the following sections, the current topics being dealt with in this especially interesting field of research are discussed.

2 The status of flotation science

According to Heinrich Schubert‘s definition, flotation is a process engineering process that numbers among the heterocoagulation separation methods [2]. It is the only mechanical separation process in which interfacial chemistry can influence the separation characteristic of wettability.

Currently, the leading international institutes focusing on flotation research are predominantly located in Australia, South Africa, Chile, Brazil, China, the USA and Canada. However, in Europe too, especially in Poland, France, Great Britain, Scandinavia and also Germany (Fig. 1), an increased activity in this field is taking place under the auspices of the European Research Framework Program Horizon 2020, and driven by the newly established Knowledge and Innovation Community (KIC), i.e. the EIT Raw Materials.

The areas of focus in this research are particularly in the physicochemical and hydrodynamic extension of the process into the area of ultrafine particles, i.e. particles < 10 µm. In addition, more and more researchers are dealing with the possibility of achieving better processing of complex polymetallic and unconventional composite materials. These include complex ores, but increasingly also the fine particulate material flows of recycling processes. In addition, there are activities that deal with the more efficient use of process water, which extend to the use of service water, drilling water and sea water.

3 Topics of flotation research at the Helmholtz Institute Freiberg

Starting in April 2012, the HIF started developing the research infrastructure for flotation research almost from zero, even though two of the world‘s leading flotation researchers – Prof. Heinrich Schubert (1926 – 2018) up to 1990 and Dr. Hans Joachim Schulze (1938 – 2003) up to 2003 – had been active in Freiberg with their groups and had set essential accents. After six years of current progress, several main research areas can now be presented here.

3.1 Ultrafine particle flotation

In his doctorate work from 2013 to the beginning of 2018, Dipl.-Ing. Tom Leistner, now working for Omya, intensively explored the possibilities of separating the ultrafine particles by adding water-insoluble oils (oil-assisted flotation) and also the application of liquid-liquid flotation [3]. His research also led to the hitherto undescribed finding that the hydrophobic ultra-fine particles actually can float well, but that their accumulation in the flotation froth is disturbed due to the fact that the extremely fine hydrophilic tailings particles reduce the bubble collision and bubble adhesion in the pulp [4]. These research results were rewarded by the presentation of the prize for basic research by Prof. James Finch and Prof. Barry Wills at the biennial flotation conference MEI Flotation‘17. The developments in “oil assisted flotation” also found application [5] in the recovery of strategic metals and other minerals from historic mining heaps in Saxony within the framework of the r3 project SMSB funded by the Federal Ministry of Education and Research (BMBF). The mines concerned had worked deposits of complex polymetallic raw materials.

Continuing the progress of findings regarding ultrafine particle flotation, M.Sc. Johanna Sygusch has been participating since the end of 2017 in the new HIF project MultiDimFlot, funded by the Deutsche Forschungsgemeinschaft (DFG), as part of the DFG Priority Program 2045 MehrDimPart, investigating the multidimensional separation of ultrafine particles < 10 μm according to wettability, size and shape. For this purpose, a new machine development is being employed - a combined turbulent rotor-stator machine that achieves froth fractionation in deep froths. This is embedded in a programme of fundamental investigations into the particle properties.

3.2 Complex polymetallic raw materials

Thanks to the possibilities for studying highly complex raw materials and particularly particle clusters in great detail and in a statistically representative quantity with new analytical methods, such as automatic mineralogy and liberation analysis, i.e. in particular the mineral liberation analysis technique (MLA), many new developments in the field of geometallurgy have been undertaken at the HIF. The benefits of these developments are currently being especially brought to bear in the BMBF r4 joint project AFK (processing of fine-grained complex ores).

As depicted in Fig. 2, this project involving the HIF, the TU Bergakademie Freiberg and the Freiberg company UVR-FIA GmbH, as well as the mining company Saxore and the RWTH Aachen, and also under participation of the EU joint project FAME, under the direction of the British mining consultancy Wardell Armstrong, is now being brought to a conclusion in Freiberg with pilot tests on a complex ore. In these pilot tests, flotation is an important multi-step process, since it involves not just finely-intergrown minerals, but additionally precious metals (especially tin, zinc and indium) that are bonded in both sulfidic and non-sulfidic minerals. In the final stage of the pilot studies, supervised by M.Sc. Edgar Schach, the HIF‘s new acquisition – a Flotation Mini Pilot Plant (Eriez) – which is unique in Europe, will be used.

Within the framework of the EU Horizon 2020 OptimOre project, which from 2014 to 2018 dealt with complex tungsten and tantalum deposits, M.Sc. Nathalie Kupka studied the flotation of scheelite [6]. The result is not only the further development of geometallurgical flotation models, but also a better understanding of the selective separation of calcium minerals. These physicochemical research topics involving non-sulfidic complex polymetallic ores have been and continue to be pursued in projects dealing with the flotation of rare earth minerals. One current example is the BMBF project “REE NamXe”, where the mechanism of selective hot flotation of the rare earth mineral Parisit is being examined in detail. M.Sc. Duong Huu Hoang has been studying the flotation beneficiation of fine grained sedimentary apatite ore from Vietnam, as well making use of the special analytic capabilities of HIF [7].

3.3 Graphite flotation used in the recycling of lithium-ion batteries

In connection with the increasing importance of the field of mobile electronics (smartphones, tablets, etc.) and especially that of electromobility (bicycles, buses and cars) a great quantity of spent lithium-ion batteries (LIB) can be expected in future years. These products are truly polymetallic, complex and fine particulate secondary raw materials and contain strategically important metals such as lithium, cobalt, manganese and nickel, as well as large quantities of refined spherical graphite. Especially for the recycling of graphite prior to the generally pyrometallurgical utilization of the metallic components, there is still no efficient separation process, meaning that no recycling takes place.

In view of the fine to ultrafine particulate nature of the composites in the so-called black mass (fraction < 1 mm after crushing of the batteries) and owing to the surface properties of the composites, an appropriate field of study is the application of flotation for the fraction < 100 µm, which makes up half of the material. This research is aimed particularly at separating the metal-containing functional particles from the graphite, as depicted in Fig. 3. This still very new field of research, driven by the activities of M.Sc. Anna Vanderbruggen, has not only succeeded in proving that separation of these materials is feasible, but has also extended the complex raw material analysis developed for primary raw materials into this field of the very complex secondary stream of black mass, greatly improving our understanding of raw materials.

In the next three years, pioneering scientific publications as well as developments in recycling technology in cooperation with partners from German industry and science can be expected in this area.

3.4 Bio flotation

Since 2016, possibilities have been studied in collaboration with the HIF Department for Biotechnology for the specific use of microorganisms and/or their metabolites as eco-friendly flotation reagents. In this context, M.Sc. Sylvi Schrader is investigating the use of amphiphilic siderophores, which are metabolites derived from marine bacteria, as efficient and highly selective biocollectors for use in rare earth recovery [8].

As part of the BMBF project “BS2, Bioflotation of Sulfides in Seawater”, M.Sc. Guillermo Luque Consuegra has been researching marine bacteria and their metabolites since 2017 for use as selective biodepressant for pyrite in the processing of Chilean Cu/Mo deposits using seawater. During this project, several bacteria have been identified that had previously not been investigated for this application.

3.5 Water management in the flotation process

In collaboration with the HIF Department for System Integrated Metal Production led by Prof. Markus Reuter and the Department for Modeling and Evaluation led by Prof. Gerald van den Boogaart, M.Sc. Bruno Michaux has been working on the integration of process water circuits in the simulation of flotation systems in ore processing plants [9]. This is a highly topical field of flotation research. In collaboration with Outotec, the effectiveness of new modeling and simulation approaches has already been demonstrated, and currently the approach to large-scale industrial plants is being further developed and tested. This work will have the consequence that water as an important resource will be more sustainably used in the flotation process.

3.6 Basic research into mineral interfaces in flotation

The separation characteristic of the flotation process is the different wettability of mineral surfaces. This is influenced and controlled by the employed flotation reagents, i.e. collectors, depressants and regulators. Due to the not yet sufficiently understood attractive hydrophobic interactions, the hydrophobized minerals can adhere to gas bubbles and are thus separated. Flotation research at the HIF is therefore concerned with the current questions of how to quantify the wettabilities and the hydrophobic properties in a targeted manner.

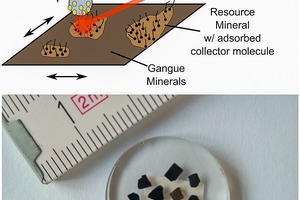

These studies make use of a special combination of modern research infrastructure, namely inverse gas chromatography for the determination of surface energies and their distribution, together with atomic force microscopy for the determination of particle interactions, coupled to Raman spectroscopy for the investigation of adsorbed flotation reagents and the mineral phases. A research focus of recent years at the HIF, under the leadership of Dipl.-Ing. Bent Babel, has been the use and further development of the technique of colloidal probe atomic force microscopy (CP-AFM) as a tool for the development of new reagent formulations and for the basic research into the hydrophobic effect on mineral surfaces [10], as exemplified in Fig. 4.

It has already been possible to develop the CP-AFM so far that it can be used in principle as a screening tool for the in situ testing of new flotation reagents on the mineral of the relevant ore. Using this tool, we are able to undertake precise mapping of hydrophobic interactions in situ and with high spatial resolution. This has prompted great interest on the part of the specialty chemicals companies that are active in the flotation reagent market, since the development and testing of new reagent regimes has up to now been very expensive. In addition, the measurement results place us in the position of being able to improve the understanding of the hydrophobic properties of mineral surfaces.

Studies of a variety of minerals using the novel method of inverse gas chromatography has succeeded in showing that wettability is a distributed and complex variable [11]. Based on the distribution of surface energy components, a new quantification of wettability was developed: the free interaction enthalpy of water-dispersed minerals with gas bubbles, which differs from the hitherto most commonly used water contact angle. It was proven that whether or not a particle will adhere to a bubble is decided by very small portions of the mineral surface.

Since 2017, the HIF has also been involved within the framework of the doctorate work of Dipl.-Ing. Hao Sheng Wu in fundamental interface-sensitive solid-state analysis in collaboration with the Department of Analytics at HIF and the HZDR Ion Beam Center. The aim of this research is to obtain better knowledge of cassiterite flotation and a better understanding of mineral surfaces in general.

4 Prospects

Absolutely in the spirit of the English play on words “the future will be fine”, we see great challenges for the flotation process in the future but also enormous opportunities with the background of the energy transition and the circular economy. We are looking forward to being joined by many strong and courageous partners from industry and science, who will accompany us on this exciting journey.

Not only at the HIF, but at the HZDR as a whole, flotation research will continue to grow. At the latest, this became abundantly clear when the Department for Transport Processes at Interface Surfaces was established at the Institute of Fluid Dynamics of the HZDR under the direction of Prof. Dr. Kerstin Eckert. This department is researching extremely interesting topics in the hydrodynamics of the flotation process.

We hope that the process of flotation and its investigation will have an important international location in Freiberg and the surrounding area, just like it did in earlier years.