Flexible, economical and highly mobile

Keestrack is presenting a representative cross-section of its full product range at bauma 2016 in the form of 7 crushing and screening units deployable in mobile processing technology for recycling applications and aggregate production.

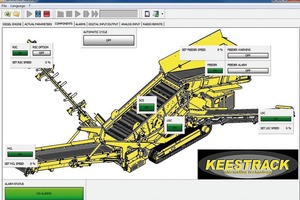

Redefining mobile processing

A high level of mobility on-site and between deployments, considerable ease of operation and maintainability and superior cost-effectiveness have for many years been the guiding principles in cross-technology development of mobile processing technology at Keestrack. Long and rugged crawler track units and statically optimised frames and superstructures facilitate rapid and simple positioning or implementation of the fundamentally support-free operating crushing and screening unit.

Crushing in all performance levels

Keestrack will be presenting proven mobile crushers at Munich as well as in particular further development and new high-end high-capacity large-scale models and the production of high-quality end-products. With transport weights of less than 30 tonnes, jaw crusher Keestrack B2 (former Argo) with a jaw width of 1000 mm and the crusher unit Keestrack R4 (former Destroyer 1011) with add-on screener and oversize material recycler again set industry standards in compact performance and/or high flexibility and efficiency with the most diverse of source materials.

This also applies to the Keestrack R8 top crusher unit (former Destroyer 1313), that is presented at Munich as a highly productive mobile solution in the output range of 450-500 t/h. As is the case for all Keestrack crusher units, the heavy construction of the 1250 mm wide rotor of the R8 and its four impact bars (diameter: 1267 mm, weight: approx. 6100 kg) and a specifically larger crushing chamber for high crushing capacities at a very smooth operation and a long service life of the tools. The standard active double-deck pre-screening with crusher bypass optimises the crushing result and minimises wear and tear.

Keestrack is announcing its new track-mounted cone crusher H4 (transport weight 35-50 t) as the first of its kind in the world. At the heart of the model designed for high-value secondary or tertiary production in the 120-200 t/h performance range is the proven cone crushing technology of a world-renowned supply partner, with whom we are working closely to optimise our machines for deployment in mobile situations.

Highly flexible screening technology

The new Keestrack C8 is now featuring for the first time at bauma. The specially adapted BIVITEC technology from Austrian development partner Binder + Co. guarantees in combination with the large screening surfaces of the double screening unit (2 x 6000 x 1900 mm) and a very broad area of application in the economic recycling of various waste materials (glass, wood, slag etc.), the processing of materials difficult to screen that have high basic moisture levels, or in the production of large volumes of standard mineral products (up to 600 t/h).

The comprehensive Keestrack range of track-mounted heavy-duty screening machines will be represented in Munich by the Keestrack K4 (former Novum). With a 4200 x 1500 mm double screen box, the compact machine offers one of the largest screening surfaces on the 30-tonne class and processes up to 200 t/h. The new mobile Keestrack D6 drum screen for organic application will also be presented for the first time at bauma 2016.

⇥Stand: FN.817/2