First AggreSandTM on Australia Shores

Mineral Washing Systems (MWS) and Terex Washing Systems (TWS) recently installed the first AggreSand™ Washplant in the Australian Market, located at Dubbo Sands Quarry in NSW/Australia. The company is one of the leading producers of sand & gravel serving Central West NSW.

Efficient Delivery and Installation

TWS, MWS and the customer, Dubbo Sands, worked together to devise a solution to meet the site specific needs (Fig. 1). After careful analysis of the feed material it was identified that a portion of the Dubbo Sands feed contained high levels of silt therefore demanding a system that would deal with this in one pass. With their old wash plant Dubbo Sands often had to wash this difficult material twice. MWS proposed the TWS AggreSandTM 165, with a three deck aggregate screen and a single sand plant. The AggreSandTM 165 provides a fully integrated feeding, screening and sand washing solution on one modular chassis. The entire wash plant including the pre-wash system was transported to Australia from the TWS factory in Dungannon, Ireland, in just seven 40 ft shipping containers. The modular, pre-wired and pre-plumbed concept of the AggreSandTM 165 allowed for rapid deployment once delivered to site. The plant was fully erected and commissioned within a matter of days.

Feed System

Dubbo Sands wanted the ability to blend varying feed materials from their site and so a dual feeder system was proposed (Fig. 2). The feeders both have a 12 m³ capacity and were configured so that the two grades of feed material can be blended at different rates before being conveyed to the washplant. Both feeders are powered from one electric hydraulic powerpack and both have remote control hydraulic tipping grids.

The blended feed material is delivered to the 16 x 5 screen by a heavy duty inclined feed conveyor fitted with a 1000 mm belt. At the head of the conveyor an integrated wash box gives the material an all-important pre-soak to pre-condition before going on to the screen.

Aggregate Rinsing Screen

The highly efficient two bearing 16 x 5 m gives a true 80 ft² screening area on each deck. The high quality polyurethane modular deck adds excellent screening and wear qualities to the aggregate rinsing screen. The screen is powered by a 15 Kw electric motor. Access around the screen is excellent with the walkways on all four sides and an innovative rolling chute to allow easy screen/module access. The inclined feed conveyor is fitted with hydraulic rams which allow the conveyor to be raised above the screen for even greater access.

The top deck acts as a protection deck while the top and bottom deck materials are stock piled by the AggreSand’s™ integrated 9 m stock piling conveyors. These conveyors each have a stock piling capacity of 150 m³. The conveyors are powered by an electric motor and have a 650 mm wide belt.

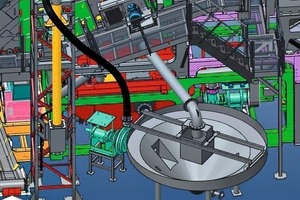

Pre Wash System

The pre-wash system is one of the first of its kind in Australia (Fig. 3). The polyurethane in the bottom deck of the aggregate screen is split 1/3 - 2/3 sections with 1 mm and 4 mm polyurethane modules respectively. The catchbox under the screen is specially designed to capture and separate the two grades of sand (0-1 mm and 0-4 mm). The fine material which passes through the 1 mm section of the screen is safely collected and piped to the pre-wash conical sump tank. The conical sump is designed to initially float off any light material (silt) with the heavier material dropping to the bottom of the sloped wall tank.

The conical sump is designed to enable regulation of incoming water and solids flowing in varying conditions without the loss of useful fines (Fig. 4). A rubber lined centrifugal pump then transfers the material from the bottom of the tank to a cyclone/separator. The separator gives a secondary cleansing of the sand and removes more material below 75 µm and sends it off to the Dubbo Sands dirty water management system. The beauty of the separator is that it has an ability to cope with varying levels of silt due to discharge regulator which ensures a constant underflow density. This ability to deal with varying silt levels was Dubbo Sands number one specification for the entire plant. The adjustable air bleed off valve enables vacuum control which affects the moisture content underflow material. The overflow material is directed towards the Dubbo Sands water management system while the underflow is piped to the AggreSandTM sand plant (Fig. 5).

Sand Plant

The pre-washed sand enters the AggreSandTM sump tank and is pumped by a rubber lined centrifugal pump to a cyclone to remove any remaining silt (< 75 µm) before being dewatered on a 12 x 5 dewatering screen. The dewatering screen is producing sand below 12 % moisture, which eliminates the need for stock pile drainage. This is a windfall for Dubbo Sands as demand is high for this quality concrete sand, which is instantly saleable and can be loaded onto a truck from the stock piler belt. In addition the plant is producing two washed aggregates from a 200 t/h feed. Niall Donaghy, Sales Manager, MWS, commented, “We were delighted when Dubbo Sands selected MWS as their preferred supplier for the washplant. The new plant is fully satisfying the customer’s aggregate washing needs. The Aggregate screen it fitted with a 65 mm top deck, 22 mm middle deck and the split 1 mm/4 mm bottom deck. The high efficient 16 x 5 m screen is producing clean aggregates which are being used as drainage stone, landscaping stone and for concrete production (Fig. 6).

//www.terex.com/washing" target="_blank" >www.terex.com/washing:www.terex.com/washing