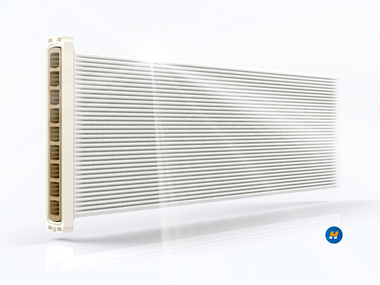

FLSmidth and ArcelorMittal reduce emissions from sinter machines

ArcelorMittal inaugurated the world’s first hybrid filter for a sinter machine at its plant in Zenica/Bosnia–Herzegovina. The filter was installed and hot commissioned by FLSmidth Airtech. Steel plants can now profitably upgrade their environmental solutions for sinter machines while also meeting future emission requirements. The hybrid filter at ArcelorMittal consists of a converted electrostatic precipitator (ESP) with a fabric filter section implemented for high productivity and environmental compliance purposes. While keeping investment and operating expenses at a minimum, this solution performs de-dusting of one of the three sinter machines at Zenica, cutting dust emissions to less than 10 mg/Nm3.

$(LEhttp://