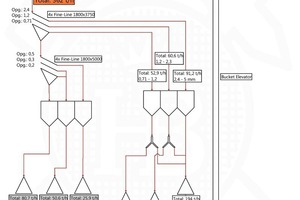

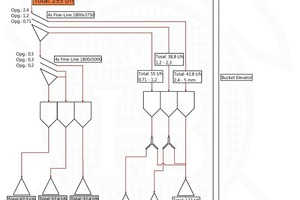

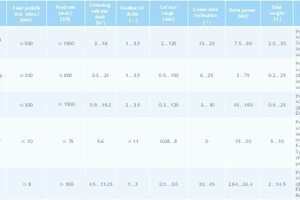

Equipment concept

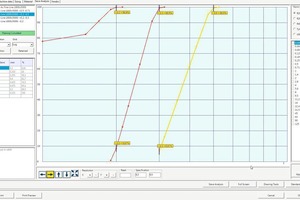

Optimizing the production of crushed sand for dry-mix mortar industrySummary: The production of dry-mix mortar aggregate requires effective interaction of suitable comminution and sizing machines. For this purpose, experimental tests on pilot or large-scale are essential. Of considerable importance for the design of the plant configuration is also consideration of the influence of mineralogical-petrographic rock properties of the raw material deposit, in order to develop for the plant operator a flexible equipment concept for long operating lifetime with high equipment availability.

1 Introduction

“Mortar” is a building material that can be described as a mix consisting of a binder (e.g. cement, lime), mineral aggregate with a maximum particle size d = 4.0 mm, and any necessary additives together with mixing water. The wide range of mortar types and their uses means that especially the mineral aggregates have to meet high requirements with regard to quantity and quality. The demand for mortar aggregate can be covered either with available natural sands or mechanical processing of solid rock.

The disadvantage of using natural sands is that the sands are only available in a...