Engineering safer conveyors

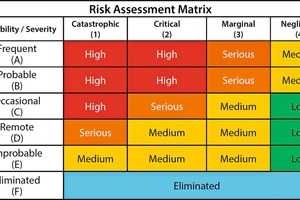

When examining the safety of a system, improving efficiency and reducing risk can be achieved by utilizing a hierarchy of control methods for alleviating hazards. The most effective way to mitigate risks is to design the hazard out of the component or system. This usually requires a greater initial capital investment, but leads to more cost-effective and durable results.

Hierarchy of control methods

Examining the US Occupational Safety and Health Administration (OSHA) accident database reveals the dangers of working around conveyors.[1] Studies have revealed that the highest prevalence of accidents are near locations where cleaning and maintenance activities most frequently take place: take-up pulley, tail pulley and head pulley.

Designing hazards out of the system means alleviating causes with the intent to bolster safety on a conveyor system. The methods of protecting workers can vary greatly. In many cases, it will be necessary to use more than one control method, by incorporating lower ranked controls. However, these should be seen as supportive measures and not as solutions in themselves.

Personal protective equipment (PPE) includes respirators, safety goggles, blast shields, hard hats, hearing protectors, gloves, face shields and footwear, providing a barrier between the wearer and the hazard. But the bottom line is that they do not address the source of the problem.

Administrative controls to change the way people work create policy that articulates a commitment to safety, but written guidelines can be easily shelved and forgotten. These controls can be taken a step further by establishing “active” procedures to minimize the risks, such as scheduling shifts that limit exposure, or more training for personnel, etc. Warning signs required by law should also be posted in plain sight, clearly understood and washed when dirty or replaced when faded. But all these measures do not eliminate the causes of the hazards. The same applies to the installing of systems such as engineering controls that allow remote monitoring and control of equipment – or guards such as gates and inspection doors that obstruct access.

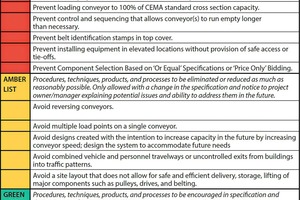

By using hazard identification and risk-assessment methods early in the design process, engineers can create the safest, most efficient system for the space, budget and application. Using the Substitute method replaces something that produces a hazard with a piece of equipment or change in material that eliminates the hazard. For example, manual clearing of a clogged hopper could be replaced by installing remotely triggered air cannons. Further examples of “Eliminate by Design” are longer, taller and tightly sealed loading chutes to control dust and spillage or heavy-duty primary and secondary cleaners to minimize carryback.

Economic analysis of prevention through design (PtD)

Prevention through Design (PtD), is a term used by the National Institute of Occupational Safety and Health (NIOSH). As a department of the U.S. Centers for Disease Control (CDC), the organization spearheaded the PtD initiative. [3] In its report, the Institute points out that studies of workplace accidents implicate “system design” in 37 % of job-related fatalities.

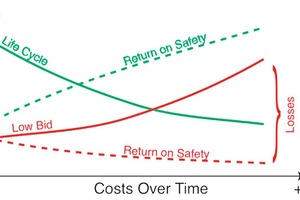

Cost is most often the main inhibitor to PtD, which is why it’s best to implement safer designs in the planning and initial construction stages, rather than retrofitting the system later. The added engineering cost of PtD is often less than an additional 10 % of engineering but has enormous benefits in improved safety and increased productivity.

Although the policy is generally not explicitly stated by companies, the Low-Bid Process is usually an implied rule that is baked into a company’s culture. It encourages bidders to follow a belt conveyor design methodology that is based on getting the maximum load on the conveyor belt and the minimum compliance with regulations using the lowest price materials, components and manufacturing processes available. But the benefits are often short-lived, and costs increase over time, eventually resulting in losses. In contrast, when purchases are made based on lowest long-term cost (life-cycle cost), benefits usually continue to accrue and costs are lower, resulting in a net savings over time. [4]

The conveyor system should not only meet the minimum requirements, but should be designed to minimize the risk and the escape and accumulation of fugitive material, thereby making the workplace safer and the equipment easier to maintain. Buying on Life Cycle Cost and anticipating the future use of problem-solving components in the basic configuration of the conveyor provides improved safety and access, without increasing the structural steel requirements or significantly increasing the overall price. It also raises the possibility for easier system upgrades in the future.

Best Practices: The “EvolvedTM Basic Conveyor”

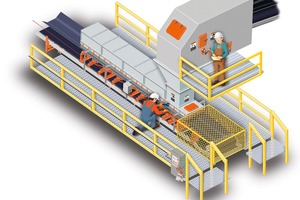

Using the Hierarchy of Controls along with the Design Hierarchy, engineers will be able to construct an “Evolved Basic Conveyor” that meets the needs of modern production and safety demands. Built competitively with a few modifications in critical areas, an “Evolved Basic Conveyor” is a standard bulk material handling conveyor designed to allow easy retrofitting of new components that improve operation and safety, solving or preventing common maintenance problems.

Maintenance-minded solutions in the loading zone, which improve safety and reduce man-hours and downtime, e.g. include slide-in/slide-out idlers, impact cradles and support cradles. On larger conveyors, maintenance aids such as overhead monorails or jib cranes assist in the movement and replacement of components. Also, designers should ensure adequate access to utilities – typically electricity and/or compressed air – to facilitate maintenance and performance. Next-generation conveyor designs may even feature a specially-engineered idler capped with an independent power generator that uses the conveyor’s movement to generate power for a wide array of autonomous equipment.

Dust, spillage and belt tracking are top concerns for many safety professionals. Field tests have shown that enlarged skirtboards and engineered settling zones promote dust settling and reduce fugitive material. Curved loading and discharge chutes control the cargo transfer for centered placement and reduced turbulence. As the load is centered on the belt, guides ensure even travel through the takeup to promote consistent belt tracking.

Any transfer point is prone to buildup and clogging under the right conditions. Flow aids such as vibrators or air cannons on chutes can sustain material movement, improve equipment life and reduced the safety hazards associated with manually clearing clogs.

Conclusion

Engineering safer conveyors is a long-term strategy. Although design absorbs less than 10 % of the total budget of a project, additional upfront engineering and applying a life cycle-cost methodology to the selection and purchase of conveyor components proves beneficial – for a longer operational life, fewer stoppages and a lower cost of operation.

Literature

[1] Conveyor Accident Database, OSHA, US Dept. of Labor. Washington, DC. 2018. https://www.osha.gov/pls/imis/AccidentSearch.search?acc_keyword=%22Conveyor%20Belt%22&keyword_list=on

[2] “Foundations for Conveyor Safety”. Ch. 31, pp. 404-440. Martin Engineering. Worzalla Publishing Company, Stevens Point, Wisconsin. 2016. https://www.martin-eng.com/content/product/690/safety-book

[3] Howard, John, M.D.: Prevention through Design: Plan for the National Initiative. National Institute of Occupational Safety and Health (NIOSH), U.S. Centers for Disease Control (CDC), Department Of Health And Human Services. Washington, DC. 2010. https://www.cdc.gov/niosh/docs/2011-121/pdfs/2011-121.pdf

[4] Swinderman, R. Todd: The Economics of Workplace Safety: Putting a price on material handling mishaps. Coal Age. Vol. 123, No. 3, pp. 28-31. April, 2018. https://www.coalage.com/features/the-economics-of-workplace-safety/

![1 Safety improves as the type of hazard control moves higher up the hierarchy of methods [2]](https://www.at-minerals.com/imgs/1/6/7/6/5/8/6/tok_13d419cfbd4394756883e00e28e8c53e/w300_h200_x600_y396_MartinEng-01-4dc743920b7bb994.jpeg)

![2 Incorporating effective hazard control techniques is easier and less costly in the early stages of a project [2]](https://www.at-minerals.com/imgs/1/6/7/6/5/8/6/tok_a082ec950b61fbbba42011695f609cde/w300_h200_x600_y414_MartinEng-02-9f04d70522df4c03.jpeg)