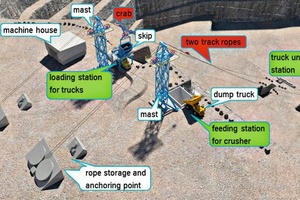

A new approach to steep-angle conveying in quarries and smaller open-pit mines with thyssenkrupp’s Skip Way System

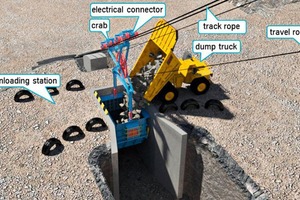

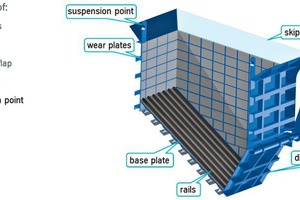

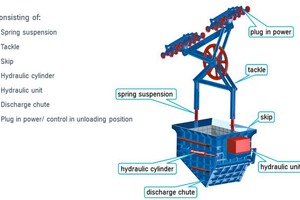

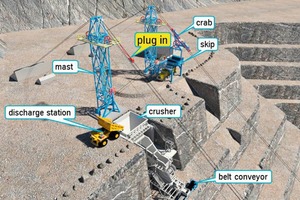

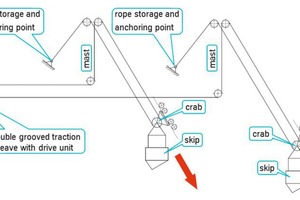

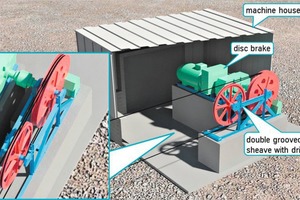

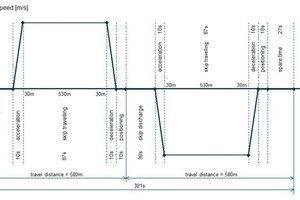

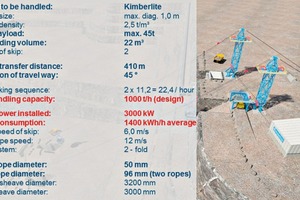

Energy-balancedSummary: Balanced-skip haulage systems are one of the mining industry’s most mature technologies. Now thyssenkrupp offers the advantages of rope running incline skips to open pits and quarries where haul truck operating costs are reducing profitability. The capital and operating economics of that system are very compelling, with dramatic reductions in CO2 emissions. With this system, haul trucks have a short, flat haul before discharging their loads into a waiting skip. With a system capacity of more than 2000 t/h, a skip conveys unfractured ore or excavation material to the upper mine rim to feed a crushing station with downstream long-distance conveyor. Alternatively – in the case of excavation material – even heavy duty vehicles can be loaded for further transport.

Quarries and open-pit mines for ores, building materials, minerals and coal are often characterized by steep terraced slopes formed over many decades by blasting and material removal. Depending on the stability of the ground a slope angle is chosen that will prevent slippage, particularly in loose rock and in regions at risk of earthquakes.

The terraced slopes with inclines from 25 to in some cases 75° are intersected by slowly rising roads that carry heavy truck traffic and also secure access to the mine. The serpentine roads generally have two lanes or feature lay-bys to allow two-way...