Dresden - The Capital of Materials - Hosting Materials Week

Based on the historic example of the three-week Werkstoffschau with the associated conference (and more than 235 000 visitors), once held in Berlin in 1927, the German Materials Society (DGM) with its head office in Frankfurt/Main hosted the Materials Week 2015 in Dresden from September 14-17 in cooperation with the Steel Institute VDEh, Düsseldorf. It was co-hosted by the trade show “Materials for the Future” where about 80 exhibitors showed their products and services.

Today’s Materials Week sees itself as an industry get-together of mechanical engineering, sensor technology, measurement and testing technology, materials, processes and manufacturing. More than 1600 experts from the fields of mechanical engineering, power engineering, medical technology, traffic engineering, information technology and chemical engineering took advantage of the possibility to share information and experiences.

At the same time, the Materials Week provides the DGM with the platform to host symposia for experts to discuss the latest developments in their respective area of expertise. Furthermore, seminars as well as two poster evenings were held, in which material users from associated disciplines, such as the recycling technology, could enhance their expert knowledge and deal with specific issues. Worth particular mention are also the opportunities given to young scientist and practitioners, who were invited, inter alia, to a career workshop within the framework of a special forum for young talents.

Prof. Dr.-Ing. Hans-Jürgen Christ, Vice Chairman of the DGM, opened the Materials Week and emphasized in particular its practical orientation as an industrial exhibition. In his welcoming speech, Saxony’s Minister of Finance, Prof. Dr.-Ing. Habil Georg Unland highlighted the uniqueness of Dresden as a location for this event: besides the University of Excellence, the TU Dresden, there are more than 20 non-university institutions successfully dealing with issues of materials science, among others with the use for mechanical engineering (crane construction, processing equipment). Wear-resistant materials for innovative crushers will only be one topic that must be in the focus, considering alone the energy consumption of the crushing process.

According to Dirk Hilbert, mayor of the city of Dresden, the “Florence of the Elbe” is the cradle of material sciences. The combination of these branches of science with other industrial sectors, such as microelectronics, was just as much a trademark as the development of products and processes up to series maturity.

Hans-Jürgen Kerkhoff, President of the German Steel Trade Association, emphasized the combination of materials sciences with modern information technology as a specific feature in Dresden. “Innovation, that’s the sum of idea, paper (today Tablet) and material, with the innovation cycles getting shorter and shorter”. The President forecasted that the Materials Week in Dresden would emerge as an unmatched trade congress for scientific experts in the field of materials engineering.

“Today, networked thinking and acting” is an indispensable premise”, says Harald Kröner, President of the Metal Trade Association. Resource efficiency is the order of the day, in particular for non-ferrous metals, with products and waste increasingly acting as “metal sources” and “urban mining” being the resource of the future.

In his short welcoming speech, Prof. Jürgen Hirsch, Acting President of the DGM, describes the importance of the Materials Week in Dresden as the beginning of a new era of the DGM. The extensive utilization of networking with the industry as well as the cooperation between the non-ferrous and the steel industry are important pillars of the German economy, with material sciences being the basis of profound further development.

On the occasion of the Materials Week, the City of Dresden had invited for a media trip on September 16, 2015, which took place in cooperation with the Dresden Marketing GmbH, the Institute for Leightweight Engineering and Plastics at the TU Dresden and the Center for Aviation and Aerospace Technology in Saxony/Thuringia. The event started the evening before with a formal ceremony.

The trip was excellently organized and enabled the representatives of mainly technically oriented magazines to gain a great overview of the potential in the materials sector in Dresden. The focus of the excursion was on the topics New Materials and Light Construction for the automotive and mechanical engineering industry and aerospace. It was clear that, in this context, cross-thematic issues – e.g. recycling – would repeatedly come up, which were brilliantly taken up by the conversation partners of the visited facilities.

The first point of interest was the lightweight construction campus of the TU Dresden, in particular the Institute for Lightweight Construction and Plastics Engineering. The director of the institute, Prof. Hubert Jäger, explained the need for the development of new materials to be able to shape the future.

“We need energy to meet people’s demands. An important influencing factor for energy are the moving loads that need to be reduced. This is why we research in this area“, so Prof. Jäger. For example, hybrid material compounds, such as highly integrated components of carbon fiber reinforced plastic and steel are developed for the automobile of the future that shall be sporty, adequate for everyday use and affordable. He sees the task of the institute in the preparation of the industry, not for the next generation of machinery and vehicles, but for the next but one. Interesting insights in the fields of automobiles, aircrafts/aerospace and energy systems (wind turbines) were given. In the automotive sector, the construction of electric vehicles with a weight of 900 kg including battery shall be possible (InEco project). Currently, they still weigh 1 300 kg. In this context, system solutions are required, which means, no exchange of individual components, but the modification of the entire vehicle, as Dr. Ing. Jens Werner (Managing Director of the ThyssenKrupp Carbon Components GmbH) explained during the plant tour.

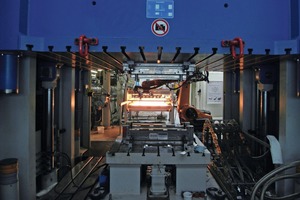

Already today, it is possible to manufacture vehicle components in one machine, where previously 15 individual machines were required.

Further interesting details were the development of lightweight wheels for busses (aluminum wheel spider with carbon fiber reinforced plastic), which in 2016 will be practically tested by the Dresdner Verkehrsbetriebe in real bus line.

Further interesting details were presented in the field of aeronautics, as for example the research on components for the A 350

with floor panels that are exposed to high stresses. Here, the non-isotropic but direction-dependent properties of the CFRP materials were utilized. To evaluate the properties of materials, a test field was set up, in which the fatigue behavior at static, cyclic and highly dynamic stress was determined. With the use of a computer tomography scanner in connection with a stress device for tensile, pressure and torsion load, crack closure effects can be excluded. A drop tower (27 m high) serves the investigation of the highly dynamic behavior and simulates accidents or the flight of birds.

In the hall for plastic applications, the most impressing feature was a radial braider with a diameter of 7 m, which is able to braid hybrid fibers and introduce steel threads and even sensors. Application examples for this are high-pressure vessels or aircraft fuselages.

In the field of lightweight construction design and structural assessment, Prof. Dr. Ing. Habil Maik Gude, Head of this Division, explained that without research work on this topic our modern mobility habits would neither be ecologically reasonable, nor economically feasible. New materials enabled the weight of the seat shells for automobiles to be reduced by 50 % or even a drastic reduction of the number of components under bending stress for the B-pillar of vehicles by using organic sheets instead of steel. With the help of bonding agents, even the combination of steel with organic sheets is possible. The division of Prof. Gude also deals with recycling issues, for example, with the recycling of CFK. One possibility for this would be a pyrolysis procedure. However, the material utilization by high-voltage fragmentation seems to be a better option, since losses do not occur. In this respect, it appears to be particularly interesting that a congress on the utilization of CFK recyclates is planned. The visit of the IMA Materialforschung und Anwendungstechnik GmbH was not less informative. Here, most different products – from prostheses up to airplanes – are tested, as Dr. Heinrich and Dr. Roth (Head of the plastics resp. metal department) explained.

For this purpose, test laboratories are available with different in-house developed test benches, for example for cyclic fatigue testing, for structural tests (strength tests for endurance testing) or for the measuring of crack extension to determine inspection intervals (aviation), to mention only a few.

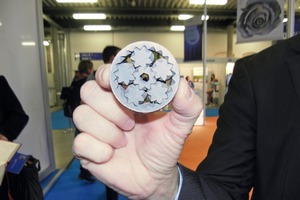

Finally a number of exhibition stands were visited at the Trade Fair „Materials for the Future“. An example is the stand of the Fraunhofer Institute for Material and Beam Technology (IWS) Dresden. Division manager Prof. Dr.-Ing. Christoph Leyens impressively explained the versatile work of the IWS for the development of storage materials and battery concepts. In the field of additive generative manufacturing, 3D printing plays a leading role, as he explained using the example of a planetary gear.

As an introduction to the fair visit, a press meeting with Dr.-Ing. Peter Dahlmann, VDEh and Dr.-Ing. Frank O.R. Fischer, DGM, both Executive Members of the Managing Board, was held. They again explained the purpose of the Materials Week Dresden, which is mainly seen in the fact that today, construction and functional materials in machine and plant engineering are more than ever perceived as a decisive factor. Based on the experiences from earlier events (1996, 1998 and 2004), which industry considered to be too scientific-oriented, this year’s focus was on bringing together developers, manufacturers and the users of materials. The success of the combination of Materials Week and Trade Fair which, from the number of registrations, was foreseeable already at the outset, is reason enough to plan the periodic repetition of the event. Dresden has proved to be the ideal location for it, thus the next Materials Week will again be hosted there. The scheduled period is September 24 - 29, 2017.