Cooling and cleaning with CLEANFIX

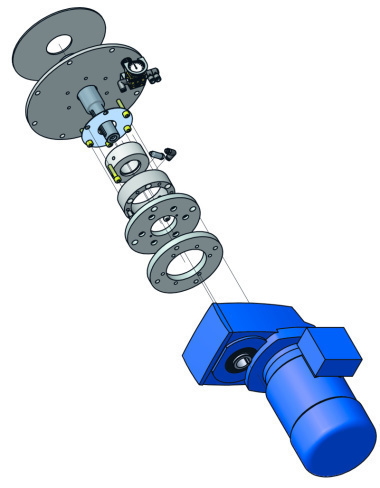

The Cleanfix family has been extended by the generation H CLEANFIX Hydronic® and developed to marketability with great research and development expenditure. Thus, the complete range of reversion fans from 320 mm to 1300 mm will also be available in a hydraulic design in the future. Special attention was paid to a long service life even with the many regulating and reversing cycles. The greatest challenge is to develop the system without any leakage up to 4000 rpm – and this with high oil temperatures as well as pressures of up to 50 bars. The new hydraulic reversion fans meet the high requirements due to the patented CLEANFIX Smart-Seal® system. This intelligent sealing system results in maximum operating safety due to the new, integrated leakage oil return for the piston seal and the rotating bushing (Fig.).

Many reference measurements from customers and manufacturers and also tests by independent test institutes, such as the Karlsruhe-based Institute of Technology, certify that the Cleanfix reversion fan saves drive power by up to 30 % with the same cooling performance as compared to electronically controlled standard fans. This means a better performance of the wheels, diesel longer in the tank and less noise since the speed can be reduced. Further attention was paid to a small installation space and also to a minimum weight.

//www.cleanfix.org" target="_blank" >www.cleanfix.org:www.cleanfix.org