Continuing to add value across a wide variety of material handling requirements

Globally respected materials handling and minerals processing systems supplier, TAKRAF, part of the Tenova group, boasts a significant portfolio of diverse and unique references across an assortment of applications; from in-plant conveyors to large scale sophisticated systems with conveyors as the backbone. Three case studies demonstrate its broad spectrum of notable conveyor applications.

Overburden removal

In surface mining, the ore body is typically beneath overlying soil or rock layers that need to be removed, transported and deposited at a location some distance away. Handling such overburden or waste material, that has no value, dictates it be conducted as quickly and efficiently as possible. This requires moving very high capacities that only conveyors can accomplish at reasonably low costs. Adding to this challenge is the consideration that must be given to system design for a number of important reasons. On many occasions it is minimizing community impact and environmental regulations that ultimately call for the re-cultivation of the impacted areas.

A waste or overburden removal system in hard-rock typically consists of a crushing station that feeds conveyable size material to an overland conveyor arrangement that brings it to a stacking facility at the deposit zone. Vast amounts of this overburden must be placed, often in layers, in a continuous operation over a very large area. High capacity extendable and shiftable conveyors are required along with mobile machines that only shut down for short periods of time to relocate or extend. When the waste removal stops so too does the production of ore.

An open pit copper & gold mine in Mexico was looking for a solution to move approximately 55 million tons of waste material per year. TAKRAF designed and supplied a material handling system with overland conveyors and stacking equipment with shiftable and extendable conveyors. The system boasts a capacity of 12 000 metric tons per hour (mt/h) and consists of an extendable conveyor with a self-propelled crawler mounted drive station, a shiftable conveyor with self-propelled crawler mounted tripper car, and a crawler mounted slewable spreader.

Commissioned in 2013, the conveyors have substituted the numerous heavy haul trucks that would otherwise be required, traveling many kilometers daily, half of the time empty, and burning diesel fuel around the clock. This system requires a vastly smaller labor force to operate and maintain with the majority of servicing conducted during pre-scheduled shut downs. The result is that getting the waste rock out of the way has caused very little impact to the planned production of the mine. Operation for the past 4 years has demonstrated both exceptional reliability and efficiency.

Moving and delivering material underground

With near surface orebodies diminishing, existing mines have to adjust their approach to meet the changing requirements of an aging mine. For many, the alternative is closure or shifting the mining operations to below the surface.

In Indonesia, an underground material handling system was recently commissioned to deliver 8000 mt/h of primary crushed ore from a new block cave to existing mill facilities above ground. The project included six underground conveyors with a total length of 4075 m and an overall vertical lift of approximately 500 m. The design, undertaken by TAKRAF’s USA office, incorporated 6000 installed horsepower per conveyor flight. At full capacity, the mine operation is capable of processing up to 240 000 t a day.

Another significant project currently being undertaken by TAKRAF Germany concerns the supply of a highly sophisticated belt conveyor system for a critical underground project in Chile. A highly innovative belt conveyor scheme will overcome a number of technical challenges including significant elevation change from the underground mine to the surface, and will comprise steep uphill tunnel conveyors that transport copper ore from underground storage bins. The arrangement will also include a number of feeder conveyors as well as an overland conveyor feeding into an existing conveying system.

The conveyor system will employ state of the art gearless drive technology with the tunnel conveyors boasting the highest power ever to be installed on a single belt conveyor. Gearless drives do not use a gearbox but only a variable speed motor having high torque throughout its speed range. With the challenges of limited space and accessibility and steep grades, the gearless solution is the main reason such a system can be achieved.

The high power for each drive permits longer flights. Meanwhile, they have a smaller footprint and reduced maintenance and increased efficiency and reliability without a gearbox.

Safety, as well as the ease and speed of maintenance are also critical success factors for operating high capacity conveyors underground. TAKRAF has developed an innovative solution that allows for regular chute maintenance to be conducted from the outside with no one having to enter into the chute. Another significant achievement will be the installation of the newly developed ST 10.000 steel cord belt on the tunnel conveyors. This will mark the world’s very first conveyor system to employ this highest rated steel cord belt technology. Additionally, with its 10 000 mt/h design capacity and total installed power of 55 MW the system will include a complex cooling system to manage and dissipate the intense heat generated within the confined spaces underground.

Pipe conveyors and their low environmental impact

Introduced in the 1970’s, the pipe conveyor has evolved as a solution for many of the drawbacks of the conventional troughed belt. Interactions between the environment and conveyed material (such as dust emissions and water absorption/contamination due to rain or snow) are eliminated by encapsulating the material while in transportation.

Further to the advantages of enclosing the material, pipe conveyors can have horizontally curved alignments which allows for elimination of transfers thereby less emissions points, not to mention lower maintenance requirements. Although TAKRAF has successfully developed curved trough conveyors for high capacity overland conveyors, the radii can be much smaller for pipe conveyors which is advantageous for negotiating facilities within a plant without the need for a lot of transfer stations.

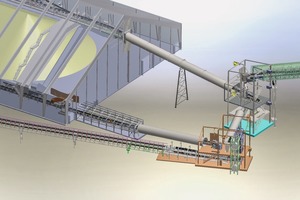

In a typical application for this type of conveyor, TAKRAF recently supplied a material handling system for a new urea plant in Enid/Oklahoma. The system provided consists of five pipe conveyors, three troughed belt conveyors, one surge bin, one portal scraper reclaimer, and one truck/train load out station.

TAKRAF pipe conveyors are employed in this plant to handle material that is extremely sensitive to contamination and in several instances curved alignments allow for a more compact plant layout. In this layout parallel pipe conveyors deliver material from the fertilizer plant to a 550-ton capacity bin. From there, another pipe conveyor distributes it to either a storage dome or new stockpile. The 90 000-ton enclosed stockpile is loaded via a travelling tripper car and reclaimed by a TAKRAF portal scraper machine. The reclaimed urea is transported via a reclaim conveyor and another pipe conveyor to a truck/train load-out station. At this load-out station, rail cars or trucks are loaded in an automated single batch system utilizing weigh bins, knife gates, and shuttle conveyors.

These examples of TAKRAF’s recent projects demonstrate how conveyor technology has advanced to meet the current demands and challenges of delivering material needed to produce the equipment and products that feed and enhance the world’s economies.

//www.takraf.com" target="_blank" >www.takraf.com:www.takraf.com

//www.tenova.com" target="_blank" >www.tenova.com:www.tenova.com