Continental Acquired South African

Tech Company

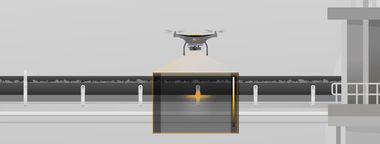

The technology company Continental has recently acquired Advanced Imaging Technologies (PTY) Ltd., based in Pinetown/South Africa, which is known for its fundamental work for x-ray and magnetic imaging-based systems used for early detecting damages in fabric and steel cord conveyor belts. Conveyor belts keep the globalized cycle of mining and industry moving. “If a belt system experiences an extended downtime, the entire production chain often collapses, intensive maintenance and often repair work is required. Monitoring systems help our customers to detect damages early and thereby reduce downtimes and save maintenance costs,” explained Hannes Friederichsen, head of the business unit Conveyor Belt Group. Up until now, technicians have had to inspect an individual conveyor belt while it is stationary or running at a reduced operating speed. The advantage of permanently installed monitoring systems is that damages to conveyor belts can be detected early, whilst the system is running, and hence be repaired in good time.

The technology developed by Advanced Imaging Technologies for international bulk-handling market uses innovative magnetic sensing technology which has been validated by extensive x-ray imaging measurements. It provides continuous online condition monitoring of steel cord-reinforced conveyor belting and reduces the risk of belt failure by providing data that is used for timely planned maintenance. This technology provides a high resolution, easy-to-interpret, magnetic image of damaged or broken steel cords for the verification of potential alarm conditions. At the same time, it gives operators real-time web interactive access to review the damage locations and their severity. In addition, the splice integrity and damage severity can be monitored over time so enabling a comparison with the historical data.

$(LEhttp://