BHS twin-shaft batch mixers replace single-shaft mixers

Summary: Austrian Baumit GmbH is among the first customers to utilize twin-shaft batch mixers of the new DMX type for the production of dry mixtures. BHS-Sonthofen specifically adapted the machines of this series to the requirements of the dry powder industry. As these machines proved greatly superior to single-shaft mixers, the Wopfing main plant has already successfully commissioned the second mixer of type DMX 4900 S in early 2017.

Baumit GmbH, a company of the Schmid Industrieholding Group, produces its entire wide range of dry building materials in various mixing lines operated at the Wopfing site. The company’s old mixing technology had reached a point where it was no longer able to keep up with the demands of modern, innovative products. For example, light weight particles rose to the top when mixing dry mortar mixtures for insulation systems. Moreover, the rapidly moving mixing units of the legacy machines destroyed fragile particles or altered the grading curve of the sand.

This gave rise to a search for a new solution. Another goal was to optimize the production capacity to meet current requirements. The management and engineers of Baumit GmbH are known for their willingness to adopt new, innovative technologies – even against the general industry trend – if these are deemed promising and deliver clear benefits.

Crushers and mixers from BHS-Sonthofen have already been in operation at the company for decades. They have proven highly successful in the production of ready-mixed concrete (Wopfinger ready-mixed concrete). Therefore, BHS performed a series of tests at their technical center based on original materials and recipes in order to prove the suitability of this product line for dry mortar production. Based on a predefined scheme, samples were extracted from the mixtures at set intervals and then analyzed at the Wopfing lab. The results fully confirmed the high performance of the BHS dry powder batch mixers. The examined parameters, ‘coefficient of variation,’ ‘screening’ and ‘water absorption,’ were mostly well below the results gained using the existing single-shaft mixers – despite shorter mixing cycles.

As a result, the first mixer of type DMX 4900 with an active volume of 4400 l was installed in the Wopfing North plant in the winter of 2014/15. Owing to highly satisfactory results, a second mixer of the same type was commissioned just one year later.

The technology in detail

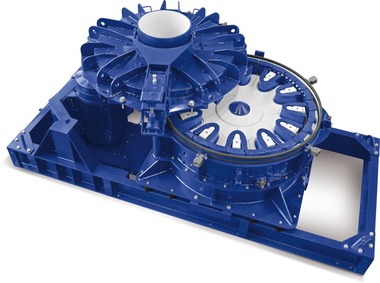

Numerous details of the dry powder batch mixers of type DMX – which are currently available for active volumes between 1000 and 5900 l – were custom configured by BHS to meet the construction material producers’ requirements.

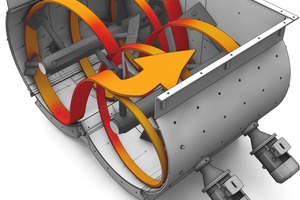

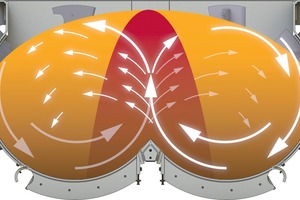

The mixing tools – designed as two counter moving interrupted spirals – guide the material transport alongside both shafts and the highly turbulent mixing zone in the central overlapping area of the mixing tools ensures intense three-dimensional mixing, even at low rotational speeds. This makes it possible to gently stir in delicate or very light components. Another advantage of the machines is their compact design. The filling level is up to approx. 90 % of the trough volume. This means that when replacing old machines, this system generally delivers much higher throughputs in the same space. Reproducible, homogenous small batches are ensured at a filling level upwards of 20 %.

The drive comprises two high-performance gears in plug-in design below the motors and an exterior V-belt power drive system. Optional frequency inverters enable continuous regulation of the rotational speed. All mixers are equipped with smooth mixing tools, a flange frame for the dust-proof attachment of a surge bin as well as mechanical mixer shaft seals protected by sealing air. BHS equipped the mixers with gapless, screwed wear linings measuring 12 to 14 mm, depending on the mixer size.

The mixer is emptied using two large hydraulic discharge flaps that run along the entire length of the trough, thus facilitating nearly complete emptying into the surge bin. The surge bins are individually designed and manufactured according to each plant’s specific requirements. The sophisticated flap sealing system efficiently brushes off particles that adhere along the perimeter. The application scope ranges from blended cements all the way to dry shotcrete with a grain size of 8 mm.

Owing to the system’s design, wear in BHS dry powder mixers is significantly lower than in single-shaft mixers of the same size. This is largely due to the comparatively lower circumferential speed of the mixing tools and to the more compact trough surface subject to wear load. In an effort to reduce wear even further, the mixers delivered to Wopfing were equipped with special blades that consist of a steel frame and screw-on plastic lips. This design leaves a very small gap between the mixing tool and trough wall. Following the production of several hundred thousand tons, only about 1 mm of the first mixer’s wear lining had worn off.

Since homogeneous mixtures can be produced at much slower rotational speeds, this directly resulted in visibly lower energy consumption. Depending on the recipe, the specific energy consumption per ton of dry mortar was reduced by up to one third as compared with the previously used single-shaft mixers.

Customizing

In the production of dry building materials, the apparent densities cover a range from 0.8 to 1.9 t/m³. BHS individually configures the machines according to each specific task. There are various drives, mixing tools and wear linings on offer for the different mixer sizes. Furthermore, several sensors on the machine allow for comprehensive production monitoring.

Taking stock

After having operated the two dry powder batch mixers for one respectively three years, the company concluded that their expectations have been met across the board: They produce homogeneous mixtures for all products of the respective mixing line, while ensuring gentle handling of the individual components. Better yet, wear and operating costs have been reduced. As an added benefit, the capacity of the entire plant has increased by about 15 to 20 % as compared with the previous single-shaft mixing system.

Ing. Roland Haidl, Production Manager at the Wopfing plant: “Here in Wopfing, we are highly satisfied with our two first BHS mixers. We are already thinking about introducing this mixing system at additional plants. BHS-Sonthofen also proved to be a flexible provider, willing and able to implement special requests and always delivering on schedule. Their reliable and competent field staff certainly contributed to our overall good impression. We also benefit from the large central warehouse based in Sonthofen, because this means that we can obtain even high-grade spare parts very quickly. This service goes a long way towards ensuring ongoing production.”