Automation for quality assurance and sampling

Whether fodder or minerals, today a reliable quality assurance requires continuous monitoring to ensure quality standards and traceability. More and more complex processes require that the fed materials correspond to the specifications. Representative sampling is an important component of quality assurance and the basis for process control. In many companies samples are taken before, during or after processing. The more close-meshed the inspection, the more accurately the production parameters can be controlled.

Traditional sampling, i.e. the manual process, is enormously labour-intensive and, of course, flawed. Often even the analyses show when the corresponding colleague is on holiday and his stand-in has taken the samples. To avoid these deviations and also to achieve the close-meshed inspections mentioned above, automated sampling may be installed to take samples at any desired time, e.g. also during the night shift when usually only a few colleagues are at work. The automatic samplers may either collect the samples for later analysis or for archiving, or they transfer the samples to downstream analysers, which is the ideal case. This type of sampling and process control helps to save operating time and to improve quality. This is capital spending that pays off already after a short time.

Of course, the type, installation point and mode of operation of the sampling system are determined by the conditions and targets of the company. It is reasonable to integrate it into the plant control (PLC) that initiates sampling proportionally to events, amount or time.

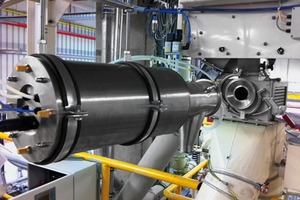

Amongst other things, REMBE Kersting has specialized in the sale and implementation of sampling in the process industry and advises customers worldwide as regards the implementation of such projects.

Hall 3, Stand 207

REMBE® Kersting GmbH

Consulting. Engineering. Products. Service

$(LEhttp://