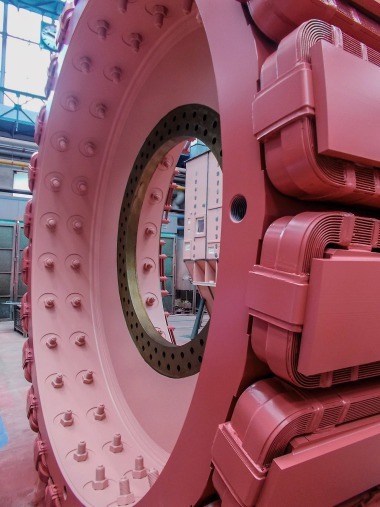

ABB mine hoist system in Ukraine

ABB has won an order to supply a mine hoist system to Zarya Mine, Kryvyi Rih iron ore plant (Kryvbaszalizrudkom JSC) in Ukraine. Being one of the mine’s key elements, the hoist will lift the ore from 1717 m depth with 50 t skips at a speed of 12 m/s.

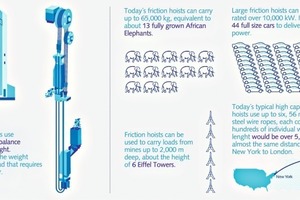

The recent order consists of the complete mine hoist system with the mechanical part equipped with hydraulic disc brakes, two 3700 MW overhung synchronous motors and an ACS6000 MV drive inverter, power transformers, medium and low voltage switchgears, a state-of-the-art control and monitoring System 800 x A incorporating underground control equipment, shaft alarm, as well as an operator control panel and a combined operator and engineering station. A complete ABB mine hoist system including mechanical, electric drive and control equipment has been in operation at Zarya Mine since 1960 without any modifications.

“Already in 2010 the plant started to use a modern electric drive, a control and monitoring system as well as disc brakes supplied by ABB with the hoist installed at Lenin Mine. With the launch of this hoist system, the plant is now able to hoist barren rock by increasing payload capacity to 35 tons and the speed to 14 m/s, while lowering hoisting energy consumption”, said Fedir Karamanyts, CEO of JSC Kryvbaszalizrudkom. The hoist system replacement with the newest equipment from ABB will enable Kryvyi Rih iron ore plant to increase productivity, reduce maintenance time and cost, cut energy consumption (Fig.) as well as improve energy efficiency. ABB in Sweden is the main contractor for this project providing manufacturing and supply of the equipment. Parts of the project will be executed by local engineering and service centers of ABB in Ukraine as well as Ukrainian partners of the company.