Screens for individual problem solutions

Screens from Merz Aufbereitungstechnik GmbH are used for a range of duties in various sectors such as the chemicals, construction, and non-metallic minerals industries, etc. The customer’s specific application generally determines selection of the screening system and design, i.e. operation as a circular-, linear- or elliptical-motion vibrating screen or even low-frequency operation. The required screening rate and the particle composition determine the necessary screen size, i.e. the open screening area of the screen. On account of the different parameters, the specific screening surface is determined in field-oriented performance trials at the Merz Aufbereitungstechnik GmbH test centre.

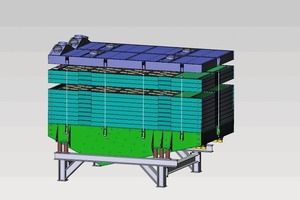

USA-type screens operate as linear-motion vibrating screens at a motor work angle of around 35° with up to three screen decks. This type is used with screening areas of around 0.5- 2.5 m² usually for simpler applications. The screening surfaces are clamped in solid frames. A combination with additional cleaning aids for the screening surface, e.g. rubber balls or ultrasonic cleaning, is commonly applied. USM multi-deck screens (Fig. 1) also operate as linear-motion vibrating screens and are generally used for high throughput rates. Depending on the number of screen cuts, 2 blocks, each with 6 screen decks, or 6 blocks, each with 2 screening decks, can be arranged on top of each other. With max. 2 lines, large screening surfaces relative to the powered volume, can be realized.

The product is distributed by means of a distributor system in the feed area combined with an upstream feeding system (e.g. fluted roll feeder). On the discharge side, the fractions are collected in modified collecting hoppers. The drive (unbalance) motors installed at the bottom are fitted, depending on the height of the screen blocks, at a work angle of around 35-40° (Fig. 2). The inserted screening panels made of wood, lightweight metal or plastic, have modular dimensions of around 800 x 800 mm and can be individually removed and replaced. Screening surfaces from 1.0 x 2.0 to (4) x 1.0 x 4.0 can therefore be realized. The screening surfaces can be combined with various cleaning aids depending on the applications. The screening surfaces are clamped into the holder frames (light metal sections) mechanically with spindle-type tensioners or hydraulically by means of cylinders.