Safe and efficient use underground

Deep below the earth’s surface, K + S KALI GmbH extracts potash crude salt, which it uses to make an extensive range of fertilizers and customized products for industrial applications to pharmaceutical salts. Work and operational safety are a top priority in the mine. For instance, to check for geomechanical changes and roof safety, inspection holes are drilled at certain intervals. With these holes, changes can be detected early on and appropriate countermeasures implemented. This is a very time consuming process as 80 km of mine tunnels must be secured and inspected in the mine today. Where crude salt is currently being extracted, 5000 inspection holes must be checked every four weeks. In addition to the inspection holes, bolts are also checked. Bolts are a type of screw-plug combination fixed into a borehole in the roof of the tool to prevent loosening and collapse of the overlying strata.

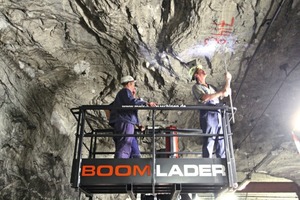

To perform this task safely, quickly and cost-effectively, the K + S managers looked for suitable machine technology. After they had been introduced to the Boomlader® concept at a trade show, it was clear to them that this unique working platform concept can solve several problems at the same time. The Boomlader® consists of a conventional, rigid Bobcat telescopic handler with attached working cage, which when the boom is in the lifted position can be controlled from the working cage (Fig. 1). Meis Baumaschinen, Bobcat contract dealer based in Reken in the Münsterland region of Germany, developed this special feature on its own initiative and perfected it ready for launch onto the market. It did this partly because no other supplier offers such a system on the market at present.

The machines converted by Meis have the necessary TÜV certificate and comply with CE standards. The special feature is that the operator of the telescopic handler no longer has to the return to the base position of the machine to drive to the next working station from the cab of the telehandler. With the boom in the extended position – with a maximum working height of 8 m – the Boomlader® can be used to control all movement and steering functions of the telescopic handler, including stabilizing processes, directly from the working cage. For all users – including the inspection hole and bolt inspectors in the potash mine at Unterbreizbach (Fig. 2) – this equipment provides considerable benefits in terms of time, efficiency and handling.

It is, however, also important that the multifunctionality of the telehandler is preserved. Thanks to the quick release feature of the Bobcat system, the working cage can be detached in minutes and a fork or shovel attached, both of which are included in the Boomlader® package supplied by Meis. For transport, the working cage measures 2.53 m in width and can be extended to 4.2 m. In both widths, the working cage can be rotated 180 degrees and is designed to carry a load of up to 320 kg (for up to three workers and tools). The Hetronic control guarantees a wonderfully safe operating feeling as the moving, steering of the telehandler and the movement of the boom of the Boomladers® can be sensitively, proportionally and easily activated and controlled (Fig. 3).

The Boomlader® was delivered to the Unterbreizbach mine and commissioned at the beginning of this year. Before the Boomlader® could be put into operation, however, Meis had to overcome several hurdles. Owing to the size of the telescopic handler, it was not possible to transport it fully assembled into the mine tunnel via the supply shaft. Consequently, the unit was delivered in several sub-components groups. These were lowered into the shaft separately and assembled underground (Fig. 4). Once assembled, the Boomlader® was tested and commissioned.

After just a few weeks of use, the user has already noticed considerable benefits. These include the safety and speed of the Boomladers®, ensuring enormous working efficiency and work safety at extremely reasonable cost. With the boom extended, the borehole inspectors can manoeuvre the telescopic handler from hole to hole or bolt to bolt without additional stabilizing being necessary as the tunnels are not usually higher than 4–5 m. Long tunnel sections can be covered by the telescopic handler in its base position, controlled from the operator cab, at a relatively good speed. In the meantime, the Boomlader® is being used for lots of other jobs in the mine. Maintenance and repair of cranes in the underground workshop, changing fluorescent lamps or hanging up roof nets above areas where workers are working are all successfully completed with the Boomlader® (Fig. 5).

Now in addition to the department for securing the roof of the mine, the electrical engineering department has indicated interest in the Boomlader®. It wants to use the Boomlader® to lay supply lines fast, safely and efficiently in the tunnels of the mine. These are usually fitted in fixed cable ducts at the top of the tunnel walls. K + S has so far used a special telescopic handler with working cage, The disadvantage of this unit is that before the cage can be lifted, the handler must be stabilized. This prevented movement of the unit when the boom was lifted, as a result of which the inspection work took a great deal of time and incurred high costs. The Boomlader® is therefore an efficient and safe tool for use in mines. The cage control is unique in Europe and pays for itself after just a short time in operation (Fig. 6). Important too is that the unit can also be used at any time for everyday telescopic handler duties with a fork or shovel, making the Boomlader® is a really multitalented machine.