Nothing off-the-peg

The grass roots of AViTEQ Vibrationstechnik GmbH lie far back in the past. For more than 70 years a large potential of experience has formed in the field of vibration technology and the related process engineering. Since 1939 drive components and complete vibrating systems have been the core business. In 1996 AEG Vibrationstechnik GmbH, Frankfurt/Main, was renamed AViTEQ Vibrationstechnik GmbH.

Two years ago the joint venture Weiteq GmbH was founded to cover the market for weighing equipment, which is also important for bulk solids handling.

The editorial board of AT INTRNATIONAL met with the two active partners Wolfgang Finger and Achim Eicke to find out more about the current development and the activities of AViTEQ Vibrationstechnik GmbH.

Finger: Our beginning dates back to 1939 starting as AEG. We launched the first series of electromagnetic vibrators on the European market. This has been developed so far that today we are the leading company as regards the technology of this type of drive. Another important milestone is that we succeeded in establishing our presence all over the world, which was historically due to the former affiliation to AEG, and which was further developed as AViTEQ. With our own companies in France and the Netherlands, licensees in the USA, Spain and England and many representations, we have taken up our present position in the international scene.

Eicke: As part of dismanteling of AEG AG in 1996, the vibrating conveyor systems was hived off as a GmbH (private limited company) and became one of various medium-sized subsidiaries of elexis AG.

Finger: Due to a management buy-out, AViTEQ has been acting on the market as an independent GmbH since 2006 – without a parent company.

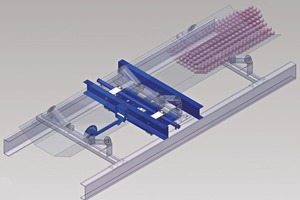

Finger: In the course of time, other drive systems have been added. From 1975 the unbalanced drives were manufactured. From the very start, complete systems were our second mainstay. Today 75 % of our equipment are particularly adapted to the requirements of the customers, i.e. only a small percentage is manufactured “off-the-peg”. We have to design the equipment to the operation temperatures, to the processes, bulk solids and to the required output, so that our actual innovation is the adaptation to the plants.

The stress on our vibration equipment with up to ten times the gravitational acceleration, and this 3000 times per minute, represents an alternating bending load, which the construction of the machine simply has to tolerate – which is not apparent just by looking at the equipment.

Finger: Yes, the customers do not want to buy standard equipment. They describe their requirements and we give them advice as to which equipment solutions are best suited for these task specifications. As a rule, our equipment has to be adjusted to existing or new complete plants.

Finger: Since 1939 we have been dealing with bulk solids. Of course, we have our application-oriented laboratory, which we have maintained for decades. There we carried out the corresponding series of measurements and evaluations. As a result, today we are in a position to make use of former measurements and experience gained with a great many materials. However, it goes without saying that today there are still many newly developed bulk solids that, if necessary, we test in advance in our laboratory,in particular, as regards screening machines and process engineering plants.

Finger: Our product portfolio also includes resonance drives, unbalanced shaft drives and proportioning drives.

Eicke: The basic materials industry is one of our main areas. We are also well positioned in recycling, steelmaking, in the plastics industry as well as in the chemical and food industries. Basically you will find us in all industries where bulk solids are processed regularly.

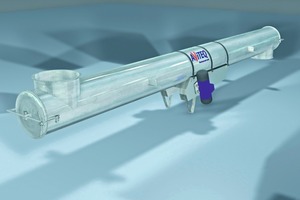

Finger: Due to the different task specifications we are permanently forced to find innovative machine solutions. This is the actual focus of our development. Of course, in addition we permanently further develop our drive systems. We are one of the very few companies combining machine building and electronics. Due to electronic monitoring of the two-mass vibrating system of the magnetic drives we are in a position to adjust the gap between the magnet and the armature In this way, we can activate larger weights with the same drive and capacity, which leads to a higher energy efficiency. Monitoring also contributes to a higher safety and longer life of the drives.

Eicke: We developed a magnetic core operating with grain-oriented material so that we can save up to 30 % of energy as opposed to competitive products.

We set up a development division at Oberboihingen, our second location in Germany, where our drives are manufactured. The focus of this department is on the further development of the magnetic and dosing drives.

AT INTERNATIONAL: What is the importance of the after-sales service at AViTEQ?

Finger: Our magnetic and dosing drives do not have any wear parts, i.e. they have a very long life and their operation is extremely reliable. If, for instance, you compare the life of a magnetic drive and that of a car engine, the life of our drives is many times longer.

If, however, drives should still failor our equipment should be damaged, there are various specialists in our service team who, in an emergency, will fly out to the user to assist him as soon as possible and to minimize production downtimes. We have installed a service hotline so that we can be contacted at any time.

Eicke: AViTEQ is represented all over the world, with two subsidiaries in France and in the Netherlands, with a joint venture in India, with licensees in Spain, England, the USA and additionally with many international representations. At present we are establishing another joint venture in China. Actually we are at home all over the world.

Our direct export quota is 50 to 60 %. In addition, however, we are exporting a great deal indirectly via our German buyers. A strong sales department is of central importance for us, in particular with these customised solutions. A strong international presence gives the customer the certainty that in case of a service requirement someone will be there quickly to help.

Finger: Weighing equipment was already part of the delivery program of AEG in the 1970s and 1980s. However, the strategy of AEG was to focus on vibration engineering. As time went on we realized that the plant construction companies increasingly place orders for larger packages again. Therefore, we decided to reactivate weighing engineering and update it. Then we found a partner who had already worked in this branch for 15 years and who had the corresponding application know-how. Thus the idea was created to found a joint venture. Our common entrepreneurial goals are: nothing off-the-peg, meet the requirements of the customers. The partner is responsible for “application engineering”, i.e. he plans the equipment to be installed in an existing or new plant. We are responsible for the design, manufacture, erection and the trial run. The complementary sales organizations of both partners are used for canvassing.

Eicke: Very frequently a combination of vibration engineering and weighing equipment is required and used so that both product ranges practically complement each other.

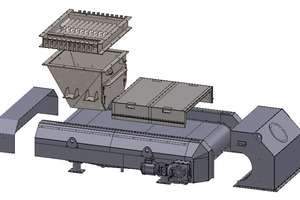

Finger: Weiteq offer all classical systems such as weigh-belt feeders and belt weighers, loss-in-weight feeders, Big Bag systems and hopper weighing machines. We differentiate between light, medium and heavy types depending on the industries in which they are used. We only install top components so that reliable and robust systems can be offered.

The buyers are basically the same industries, which we also supply with vibration equipment.

Eicke: During the last two years we have updated the design of our weighing equipment – weigh-belt feeders and belt weighers as well as loss-in-weigh feeders. This year we started actively canvassing on the market. In the meantime we were able to clock up the first successes with a reference character. For example, a large German supplier of steel mills placed an order with us for a steel mill in Venezuela.

The increasing international inquiries and the success we have had from the very beginning show that we are able to meet the requirements of the markets with our strategy and measures.