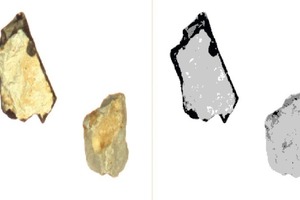

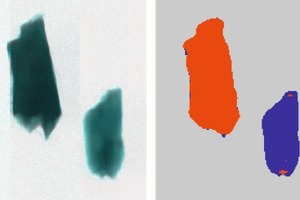

COLOR versus NIR/XRT

Sensor-based sorting of industrial mineralsAbstract

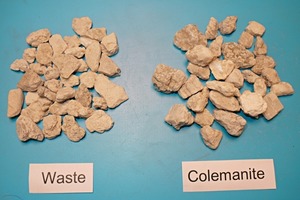

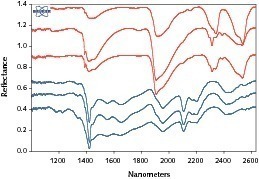

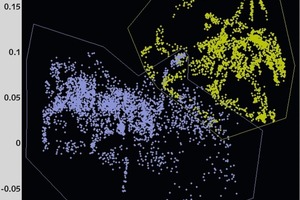

Color cameras have been used for many years in the improvement of industrial mineral products. The success of this technique depends on the product being differentiated by color from the unwanted material. New sensors are now also able to differentiate minerals unequivocally, irrespective of their colors. Significantly improved product qualities and higher product yields are thus achieved, compared to optical sorting. The benefits of sorting using a near-infrared (NIR) and an X-ray transmission (XRT) scanner become apparent upon comparison against color-camera sorting. Color-sorting of borate-containing mineral is firstly assessed against near-infrared sorting. The separation of limestone and flint, firstly by color, and then using X-ray transmission, is then comparatively assessed.

1 Introduction

Optical sorting of industrial minerals by color and brightness is state-of-the-art, and has frequently been examined in technical journals [1, 2, 3, 4]. Sorting of fillers and extenders, for example, improves quality-relevant parameters such as whiteness and yellowness index. Sorting of high-purity quartzes lowers iron, aluminium and titanium contents by rejecting colored and non-transparent impurities. The precondition for this is that the unwanted material is differentiated from the “value” (the product) by color. There must, therefore, be an adequate correlation between the...