Patently round

Analysing the service life of idlersSummary

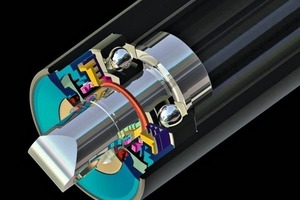

Artur Küpper GmbH & Co. KG is a German company operating at two sites and in two business sectors. Both facilities develop and engineer high-quality components for machine and plant engineering as well as for automation technology. Bottrop is the base for the development and manufacturing know-how for idlers and belt conveyor rollers. The company’s strengths include keen expertise in engineering, which has led to the development of numerous customized products, models and system solutions, which have also been patented. In this connection, the company focuses particularly on lengthening the lifetime of idlers. By way of example, the paper presents several products that have been developed together with Artur Küpper GmbH and proven efficient in the belt conveyors at the open-cast lignite mine owned and worked by RWE Power AG.

1 Calculating bearing lifetime

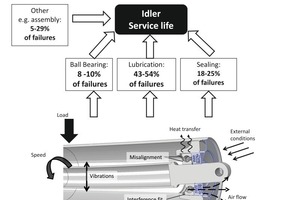

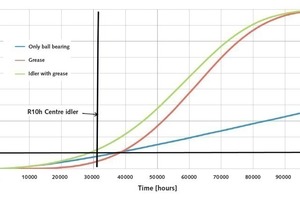

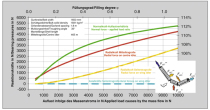

The trouble-free operation of an idler depends essentially on the mobility of the deep groove ball bearing. For this reason, in the calculation of the lifetime of an idler, the lifetime of the bearing must be taken into account (in accordance with DIN ISO 281 [1]) as a key factor. On the basis of the main parameters of a belt conveyor, it is possible to calculate or estimate the bearing failure rate. The procedure for this is shown in Table 1. The calculations were made with allowance for the measured forces. The force measurements were conducted and documented by...