High-precision dosing in compact form

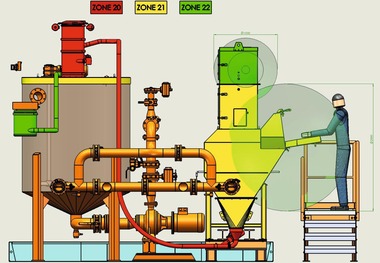

The solids solutions group has developed the PreciDos dosing screw and applied for a patent for this development. PreciDos comprises a precision dosing unit with a dedicated rapid control unit. As a dosing unit in combination with rotating bowl scales, this control unit communicates directly with the weighing terminal by means of digital I/Os. This is how the complete dosing cycle is operated. All time-relevant switching processes are disconnected from the PLC. Special pulsed after-dosing is integrated and enables correction of the smallest volumes in the gram range. For example, with the PreciDos DN65 and the GSC20 rotating bowl scales, for a cohesive metal powder, bulk density 1.8 kg/dm³, long-term dosing accuracy of ± 1 g can be achieved. The precise dosing equipment is actuated on the feed side. As a result, the screw is very slim on the discharge. In this area, no access is necessary as the seal can be removed through the screw tube. A horizontal agitator in the screw inlet ensures uniform filling of the channels. PreciDos can be easily dismantled for the purpose of cleaning. The stable back panel onto which the two electric drives, the entire pneumatics and the electric control unit are mounted can be retracted together with the screw flight and the agitator on a rail with roller scales. In addition, the screw tube can be taken off at the front. The sizes DN65, DN80, and DN100 are available. The concept is modular so the optimum components can be selected for each specific application (Fig.). The equipment is suitable for use in EX zones.