Minimized clogging – optimized drying

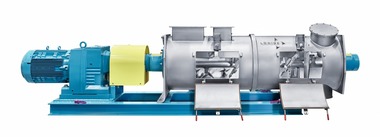

The fluidized bed process is mainly used for drying or for combined drying and granulation. Heated fresh air is supplied into the machines from the bottom via a perforated plate. The flow moves the product circularly and keeps it floating. This ensures a particularly gentle and effective handling. Lödige have continuously further developed this process with their fludized bed processor LFP. Specially shaped Conidur perforated plates ensure a horizontal airflow over the entire vessel bottom running annularly with the wall. In this way, pulsating and bubbling within the fluidized bed are prevented to a great extent and drying as well as the mixing effect are optimized. A newly developed perforated plate (Fig.) now improves the product movement inside the mixing vessel and reliably prevents particles from sticking to points with low motion. The machine has been designed for batches of up to 50 kg and can be used by the company for product-specific tests.

Gebr. Lödige Maschinenbau GmbH, Paderborn (D),

Tel.: +49 5251 309-0, www.loedige.de