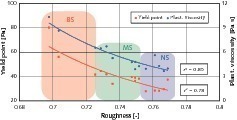

The future of crushed sands?

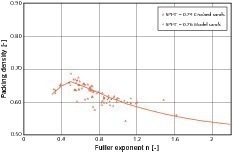

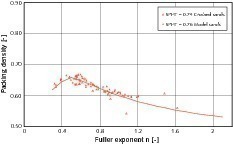

Influence of the sand grain shape on the working properties of SCC mortarsSummary: In this paper, as the culmination of extensive tests, a method is presented which can be used to estimate the behaviour of crushed sands in SCC mortars in advance. The algorithm described provides an initial basis for an empirical model that enables the derivation of information on the working properties of SCC mortars from only the results of analysis of the grain shape and grain size distribution of the starting sands. The key parameters are the Fuller exponent n of the grain size distribution and the shape parameters sphericity and roughness.

1 Introduction

Crushed sands are usually a by-product of the production of ballast and chippings, accounting for up to 20% of the yield. With simple comminution methods, crushed sands with a fine grain content of 15-25 mass % are produced “by the way”. They are only used in high-grade applications providing the entire comminution and processing flow undergoes cost-intensive optimization. Depending on the regionally dependent availability of extracted materials, however, they are currently either just dumped or used for inferior backfilling, as cable sands or in frost protection courses.

The...