Reduction in costs and improved safety

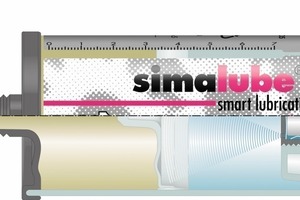

Simatec ag from Wangen an der Aare in Switzerland is manufacturer of automatic lubricators. simalube automatically lubricates for periods from one month up to a year. The required time period can be adjusted on the dispenser. It is driven by the globally patented gas producing dry cell. The gas generated by the cell builds up the excess pressure in the dispenser behind a piston, and this automatically and evenly pushes the lubricant into the lubrication point (Fig. 1). The grease and oil dispenser is screwed in directly at the lubrication point instead of the grease nipple. The practical parts in the simatec ag accessories range ensure that the simalube can easily be installed everywhere, in any position and 360 degrees around its own axis. There is a vast range of possible applications (Fig. 2): conveyor belts, fans, motors, pumps, cooling and heating units, chains and guides are all reliably supplied with grease or oil by the Swiss lubricators. simalube works upside down and even under water. Its operating temperature range is from -20 °C to +55 °C.

Driven by a gas producing dry cell manual lubrication is no longer required. As a result of the time saving alone, costs are considerably reduced and manpower resources are freed up for profitable tasks in the value chain. The simalube lubricator ensures reliable and even application of lubricant, resulting in less damage to bearings and longer machine operating times. The simalube closed system prevents any penetration of dirt. This extends the service life of the lubricated components and ensures reliable operation of the equipment - and no lubrication points are overlooked or forgotten.

Lubrication points are often located in places that are difficult and dangerous to access. simalube helps reduce the number of maintenance and inspection rounds required. The automatic dispenser makes it easier to comply with occupational safety standards, which in turn results in significantly fewer occupational accidents. simalube lubricators are tested according to the latest standards of product safety. They are approved for use in all areas with potentially explosive atmospheres, with gases, dusts and even in mining.

When the lubricator is empty, it can easily be refilled or disposed of in an environmentally friendly way. This is possible because the dispenser does not contain any toxic liquids such as acids etc., and all parts can be recycled. The gas producing dry cell is disposed of like an ordinary battery, and the empty dispenser case is disposed of in the same way as normal waste. The simalube comes in four different sizes (30 ml, 60 ml, 125 ml and 250 ml), with over 10 tried and tested standard lubricants. This ensures far greater flexibility of use. simatec ag also provides empty dispensers for customers to fill with their own grease or oil. Accessories developed by simatec ag are used for many different and complex applications of simalube lubricators.

simatec ag, Wangen an der Aare (CH),

Tel.:+41 32 636 50-00, www.simatec.com