New simulation tool

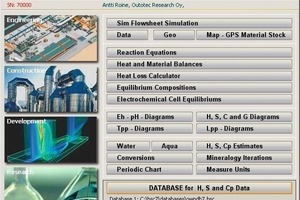

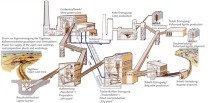

Modelling and simulation supply the answer to navigating the ever-growing oceans of data that threaten to engulf us. The new HSC Chemistry 7.0 (Fig. 1) from Outotec Research Oy, of Pori/Finland is a straightforward simulation tool designed to guide process development and research scientists. HSC is a software program for process flowsheet simulation, which also contains 22 other calcula-tion modules displayed as options in the main HSC menu, and 12 databases together with extensive thermochemical, heat transfer and mineralogical data. HSC Chemistry 7.0 is compatible with Windows Vista, Vista 64 and Windows 7.

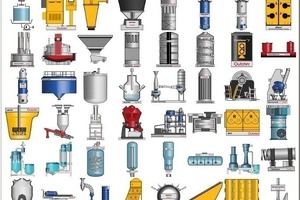

The Flowsheet Module of HSC Chemistry 7.0 has four different modes – Particles, Reaction, Distri-bution and Experimental – with new, dedicated tools. There are new drawing features, high-resolution icons, a new table facility, new page and layer properties, new spreadsheet features, and new Excel Wizards with more commands, as well as Mass Balancing and Data Reconciliation routines. The new Unit Icon Library comprises 515 high-resolution icons that have been created to visualize process flowsheets (Fig. 2). There are nine new Add-In Functions – StreamSM, StreamGM, StreamEQA, Stream-XArray, RecoveryXArray, Progeny-Stream, ComminutionProductPSD, CubicSpline, and ERF.

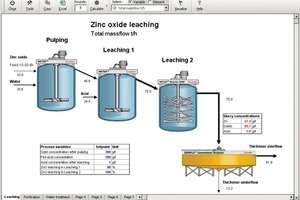

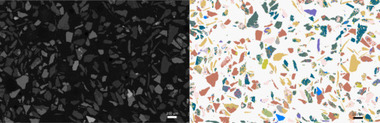

During mineral set-up there is direct access to the HSC Mineral Database, complete with its new Mineral Database Browser. There are improved liberation data-processing tools as well as enhanced unit models of mineral processing equipment to provide more detailed data on particle size, density, composition and distribution. The Mineralogical Database has been hugely increased – from 3 581 to 13 346 minerals with better integration with process models (Fig. 3).

The new Distribution mode makes it possible to work with high temperature process models. The new Experimental mode enables the visualization of stream properties and the development of experimental data tables. All calculation modules automatically use the same thermochemical database, which contains enthalpy (H), entropy (S) and heat capacity (C) data. This H, S and Cp Database has been comprehensively enhanced to include over 4 000 new species, and the existing data on

4 700 species have been updated. The total number of species now exceeds 25 000. The data is based on the massive amount of experimental work carried out over the last hundred years in laboratories all over the world.

Outotec Research Oy, Information Center, Pori (Fin)

Tel.: + 358-20-5293106, E-Mail: hsc@outotec.com,