BHS-Sonthofen GmbH

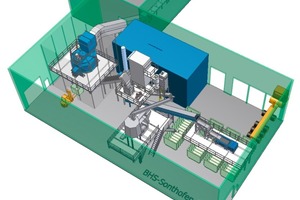

Based on the experience gained in the rock industry, BHS started to develop innovative comminution machines for the recycling industry more than 10 years ago. The company offers complete system solutions for the processing of electronic scrap, refrigeration units (Fig.), light shredder fractions, slags and other valuable materials. BHS produces continuously and batchwise operating filters for solid-liquid separation. They are predominantly applied in the chemical industry and for environmental technologies.

At the IFAT ENTSORGA 2010, BHS-Sonthofen will demonstrate their competence as regards the dry mechani-cal processing of potential recyclables. Various material samples from different process stages of typical applications will be shown. The focus will be on the following applications:

• Electric and electronic scrap including refrigeration units

• Light shredder fractions

• Slags of all kinds

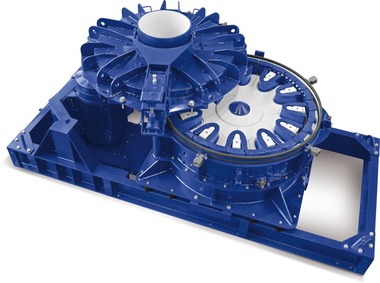

A decisive step in the processing of such materials is the selective comminution of the feed. The objective is material preparation which ensures a subsequent safe separation with a highly homogenous output. Machines from BHS can be configured and adjusted according to numerous parameters.

In addition, BHS-Sonthofen will present for the first time at the IFAT ENTSORGA 2010 the new IC process for the recycling of refrigeration units containing chlorinated fluorohydrocarbons and hydrocarbons (e.g. pentane). The abbreviation “IC” stands for “Impact” and “Catalyser” as core elements of the innovation. It is based on the low-wear impact comminution principles of the BHS rotor shredder. The economic processing of all coolants and expanding agents by means of catalytic hydrolysis is a completely new process. An expensive inerting of the crusher with nitrogen is no longer necessary. With this process all legal regulations and limit values of the EU are fulfilled without any problem. In particular, the patented IC system from BHS is attractive with higher plant performance since the operating costs, compared to the traditional processes, are clearly more favourable, and practical experience is already available.

Hall B3, Stand 331/434; www.bhs-sonthofen.de