Service is given top priority

First Bulk Materials Handling Press Day, Essen/Germany (08.10.2009)

On Thursday October 8, the first Bulk Materials Handling Press Day (Fig. 1) was held on the premises of REMA TIP TOP Dr. Nordmann GmbH. REMA TIP TOP was present with all of the expertise that the company has to offer. REMA TIP TOP GmbH, an independent company within the STAHLGRUBER Group, has achieved international renown for high-quality products and professional services throughout its 80-year success story. The Industry Division offers its customers specifically-tailored solutions of which aftersales service is an integral part.

The company offers, for example, several innovations in the field of belt cleaning systems. There is a new belt cleaning series, REMACLEAN HM-U4 to HM-U8. The innovation in this REMACLEAN (Bild 2) series is the new geometry of the belt cleaning strip that permits a better fit to the curved surface of the conveyor belt. This allows an optimum and even downward pressure of the cleaning strip across the entire width of the load-bearing side of the belt to gently clean the surface.

For plant operators, it is important to minimize downtimes to remain economically sound. Amongst other things, the correct pulley lagging can play a role, since conveyor belt pulleys require coverings that can handle the conditions – in the same way that cars require the right tires. Here a difference must be made between tail and tension pulleys, inflexion rollers and snub pulleys as well as drive pulleys. All pulleys, however, have the same requirements, such as high wear resistance, weather and temperature durability, or they may even have to resist chemical influences. REMA TIP TOP determines the exact requirements in intensive discussions with customers and offers solutions in the form of elastomeric or ceramic-elastomeric coverings (Fig. 3).

REMA TIP TOP has also gained a great deal of experience in the field of ceramic linings and coatings used for corrosion protection in the plant. Numerous application examples for linings and coatings were shown. In the area of coatings, there is a complete set on offer, from oscillating conveyors through to material guides and pipelines. In the area of spray coating technology, tank interior coatings, water treatment plants, base coatings and coatings in various other segments were displayed. REMA TIP TOP here uses the polyurethane REMACOAT material, which has proven itself internationally in many different fields of application.

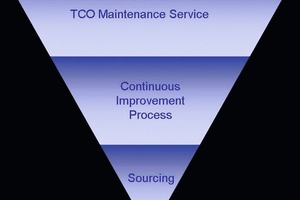

After a factory tour and several practical demonstrations in the grounds of REMA TIP TOP Dr. Nordmann GmbH Essen facilities, the subject of service, shown with the help of operator and TCO (total cost of ownership) models, was examined in detail. The key element is the TCO maintenance service including the actual inspection and the proactive maintenance of the corresponding plants or plant parts. Immediately after starting the service activities, a continuous improvement process is initiated in which the plant operator actively takes part. Longstanding business relationships with suppliers make it possible to procure the many different spare parts and consumables on easy terms. Optimum maintenance of the plant and, consequently, lower maintenance and repair costs, are in the interests of both the plant operator and the service provider.

REMA TIP TOP’s market position is defined by its thorough approach to service, and it is one of the company’s unique characteristics. The service-oriented thinking that characterizes the company throughout the world is made possible by means of a global network. REMA TIP TOP is represented in over 200 countries and in addition is involved in many associated companies and service operations. This network, coupled with a high degree of professional expertise, simplifies the daily business of the plant operator to a considerable degree.