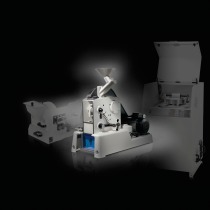

The compact pre-crusher

The compact FRITSCH Jaw Crusher PULVERISETTE 1 (Fig.) is the ideal instrument for fast and effective pre-crushing of hard and very hard brittle materials – even ferrous alloys are no problem for this instrument. It is available in two different models for various feed sizes up to 95 mm and sample quantities in a final fineness of 1-15 mm. The comminution of the sample takes place in the Jaw Crusher under high pressure between one fixed and one movable crushing jaw in an enclosed grinding chamber. The final fineness is easily set from the outside with the 10-stage adjustable gap width between the crushing jaws. Crushing jaws and lateral support walls are available in various steel types, tungsten carbide and zirconium oxide – optimal for RoHS-samples and for iron-free pre-crushing. The ground sample automatically falls downward – into a drawer for batchwise comminution or via a chute into a larger collection container for continuous operation or directly into a FRITSCH Disk Mill PULVERISETTE 13 for further comminution to a final fineness of down to 100 μm.