Benefits of overband magnet armoured belts

18.09.2024The highest wear part on an Overband Magnet is the belt that transfers the separated metal away from the conveyor and into a collection area. In order to reduce such wear, Bunting developed a special lightweight armouring for the rubber belt. This type of excessive belt wear occurs in heavy-duty applications seen in mining, recycling, and biomass power plants.

Bunting ElectroMax Overband Magnet with an armoured belt

Bunting ElectroMax Overband Magnet with an armoured belt

© Bunting

In operation, an Overband Magnet sits over a conveyor transporting materials such as aggregate, waste, shredded wood or mined ore. The magnetic field of the Overband Magnet, generated by either a permanent magnet or an electromagnetic block, attracts ferrous metal from the conveyed material up and onto the revolving self-cleaning belt. Rubber upstands on the belt catch the lifted metal, transporting it away from the conveyed material into a separate collection area.

The force of the ferrous metal striking against the self-cleaning rubber belt is significant due to the magnetic attractive energy of the permanent or electromagnetic block increasing as the metal moves closer to the face. This means that the metal is accelerating into the belt. The moving belt becomes sandwiched between the lifted metal and the magnetic block momentarily, until the upstand catches and drags the item away and out of the magnetic field.

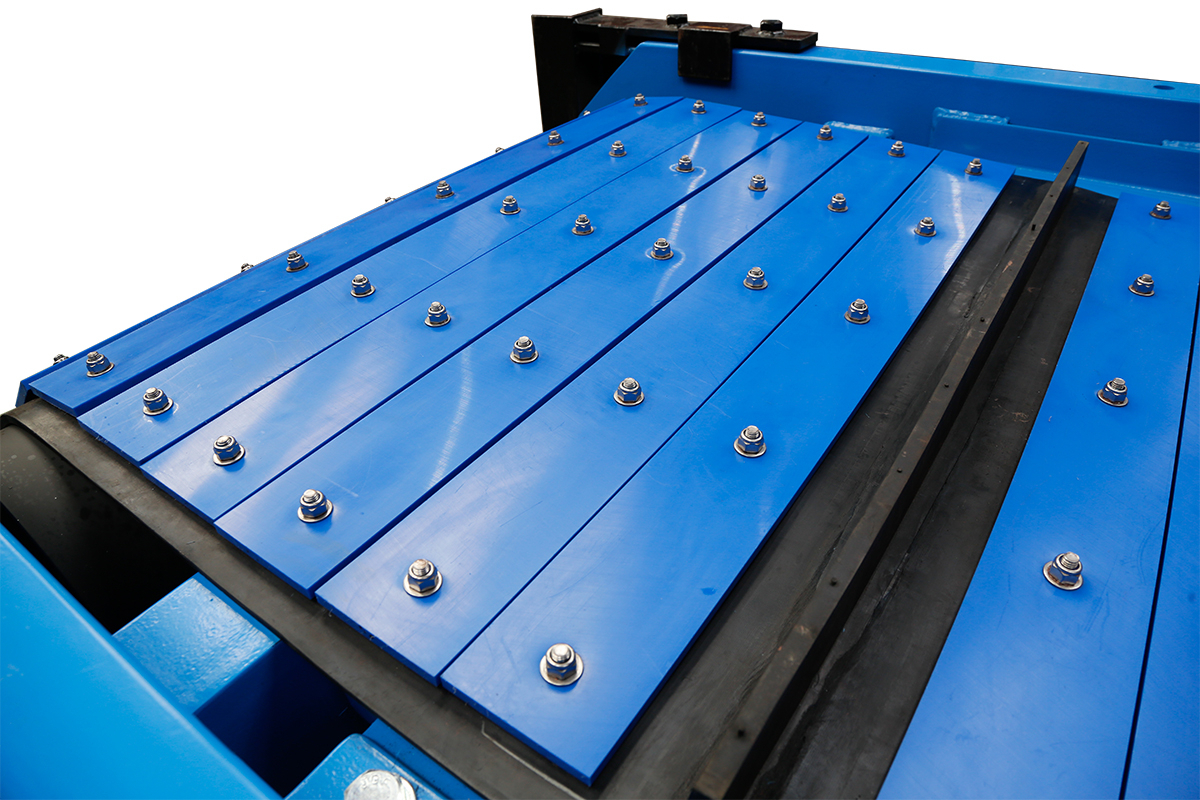

Close-up of the armoured belt

Close-up of the armoured belt

© Bunting

Applications in which self-cleaning belts experience high levels of wear include:

- When there are high amounts of ferrous metal present in the conveyed material;

- When the ferrous metal is large and heavy;

- When there are nails or thin and sharp ferrous metals;

- When the magnetic block has additional magnetic force, as with the ElectroMax and ElectroMax-Plus models;

To combat the excessive wear and extend the life of a self-cleaning belt, Bunting’s engineers designed a lightweight but heavy-duty armouring for the belt. There were other options, including special wear-resistant belt coatings and other types of rubber belt. However, the armouring provided unrivalled protection, significantly lengthening belt life.

Bunting's Permanent Overband Magnet with an armoured belt

Bunting's Permanent Overband Magnet with an armoured belt

© Bunting

The armouring on the rubber belt is comprised of high-density polyethylene (HDPE) slats. Each slat is 100 mm wide and 10mm thick, with a length to suit the model of overband magnet. The slats are fastened to the belt using special 304 stainless steel elevator bucket bolts and nyloc nuts.

“The introduction of this design of armoured belt has proven very popular,” explained Adrian Coleman, Bunting’s Technical Director. “Other types of belt armouring have proven unsuccessful, but the HDPE has worked exceptionally well.”